Let’s explore what each one does and how they’re used.

OD Grinding

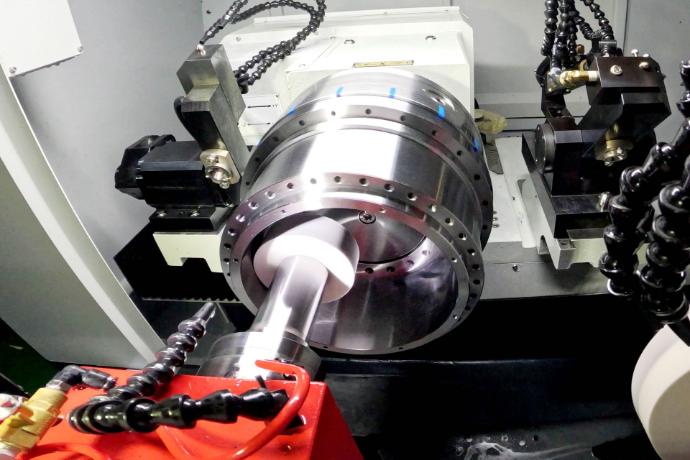

OD grinding, or Outer Diameter grinding, is used to remove material from the outer surface of a rotating cylindrical part. The goal is to achieve a precise diameter and smooth surface finish while maintaining roundness and concentricity.

ID Grinding

Color blocks are a simple and effective way to present and highlight your content. Choose an image or a color for the background. You can even resize and duplicate the blocks to create your own layout. Add images or icons to customize the blocks.

Surface Grinding

Surface grinding creates smooth, flat surfaces. Unlike OD and ID grinding, the workpiece typically stays still or moves linearly while the grinding wheel removes material from above.

OD grinding is typically performed on cylindrical parts like:

• Shafts

• Rollers

• Sleeves

• Pins

Since the part rotates during grinding, this method is perfect for components that must stay symmetrical. e-tech’s CNC cylindrical grinders are built to handle tight tolerances with consistent performance.

Common applications include:

• Bushings

• Bearing races

• Hydraulic cylinders

• Sleeves with inner diameters

In ID grinding, the wheel enters the part, requiring high spindle stability and careful setup. e-tech’s Universal Internal and OD grinders allow both internal and external surfaces to be machined in one setup, which improves precision and efficiency.

Surface grinding is ideal for:

• Tool and die components

• Precision plates

• Mold bases

• Fixtures and jigs

Surface grinding is often the final machining step, ensuring flatness and surface quality. e-tech’s Surface Grinder Series provides high-precision results across a wide range of part sizes and types.

Feature One

At e-tech, we specialize in building grinding machines that support all three processes, with models designed for flexibility, accuracy, and long-term reliability. From CNC cylindrical grinders to universal ID/OD machines and precision surface grinders, our lineup is engineered to meet your needs across a wide range of industries.

Looking for guidance on which grinding solution fits your application best? Get in touch—we’re here to help.

在這裡開始寫入