What Is CNC Grinding?

Why It Matters in Modern Manufacturing

Precision and consistency are no longer luxuries in manufacturing—they're the baseline. That’s where CNC grinding steps in. Whether you’re producing components for aerospace, automotive, or general machining, this method helps ensure that every part meets tight tolerances and surface requirements.

If you’re curious about how CNC grinding works, or you’re looking to integrate it into your process, this guide covers the basics—what it is, how it's used, and why it matters.

Understanding CNC Grinding

At its core, CNC grinding involves using a controlled abrasive process to remove material from a workpiece. What sets it apart is that the movements—like positioning the grinding wheel, adjusting feed rates, or controlling tool paths—are all handled automatically by a CNC (Computer Numerical Control) system.

The grinding wheel itself is made of abrasive materials that chip away at the surface with extreme precision. CNC systems allow that wheel to follow exact patterns and speeds, so the outcome is repeatable and consistent—even for parts with complex geometries.

Common Types of CNC Grinding

Depending on the application, you might see one or more of the following types of grinding in a shop or production line

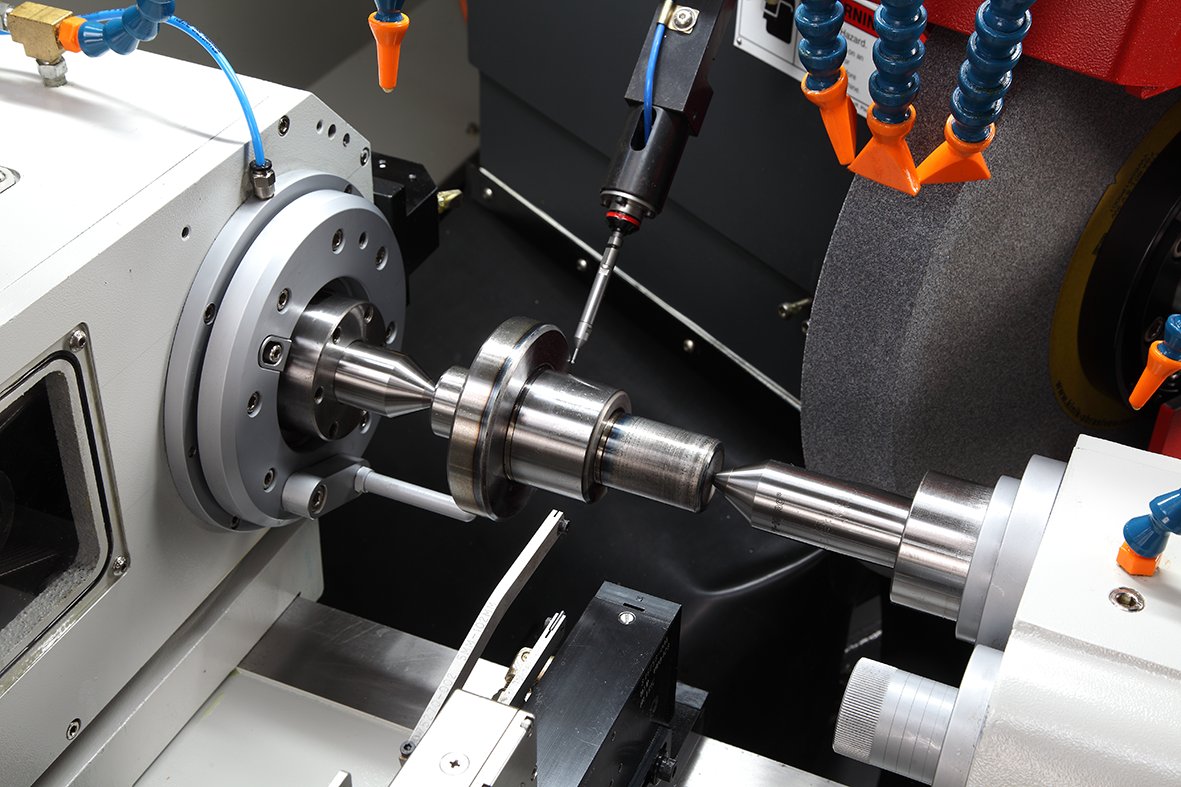

OD Grinding

OD, or Outer Diameter grinding, is used when the external surface of a cylindrical part needs to be shaped or finished. The part spins while the grinding wheel moves toward it or along it—perfect for shafts, rollers, and similar components.

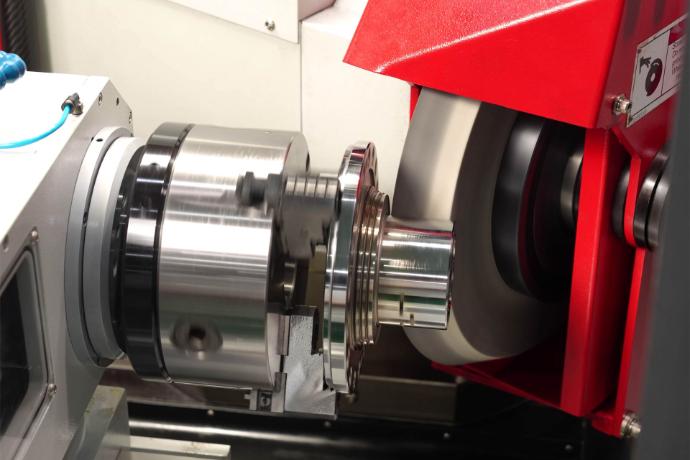

ID Grinding

OD, or Outer Diameter grinding, is used when the external surface of a cylindrical part needs to be shaped or finished. The part spins while the grinding wheel moves toward it or along it—perfect for shafts, rollers, and similar components.

Surface Grinding

Internal Diameter (or Inner diameter) grinding is used inside hollow parts like bushings or bearing races. The wheel enters the bore and machines the internal surface with high precision.

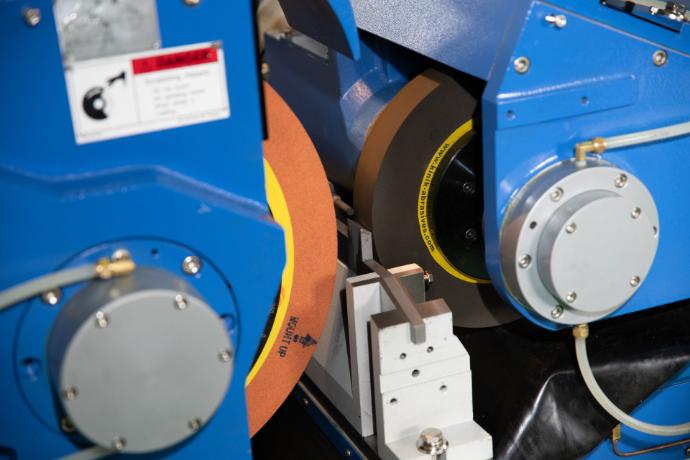

Centerless Grinding

Unlike OD grinding, centerless grinding holds the part between a grinding wheel and a regulating wheel—no need for chucks or centers. It’s ideal for high-volume production of round parts.

Vertical Grinding

Vertical grinders feature a vertically positioned spindle and often a rotary table. This setup enhances workpiece stability thanks to gravity, making it ideal for grinding large or heavy parts—particularly on face, ID, or OD surfaces.

Why CNC Grinding Is So Effective

CNC grinding stands out for several reasons:

01 Extreme accuracy

Machines can reach micron-level tolerances.

02 Repeatability

Once the program is set, it can run identical parts with no variation.

03 Versatility

Many modern grinders can perform multiple operations—like OD, ID, and face grinding—all in a single setup.

04 Automation-ready

CNC systems easily integrate with loaders, tool changers, and even in-process gauging for real-time feedback.

Industries That Rely on CNC Grinding

CNC grinding machines are widely used across sectors that need precision parts:

Why It Matters More Than Ever

With today's manufacturing challenges such as tighter tolerances, shorter lead times, and the push toward automation, CNC grinding plays a key role in helping companies meet expectations. It’s more than just a finishing process. In many cases, it’s a strategic tool for reducing production time while maintaining top-level quality.

Technologies like conversational interfaces (e.g., iGrind), automatic tool changers, and AI-powered parameter optimization are helping make grinding not only more accurate, but also more accessible, even for operators without years of experience.

Final Thoughts

CNC grinding might not be the flashiest process on the factory floor, but it’s one of the most critical. If your operation demands parts that meet strict tolerances, a CNC grinding machine could be the most valuable investment you make.

At e-tech, we offer a full line of grinding solutions including cylindrical, centerless, internal, and surface grinders all made in Taiwan and engineered for performance. Whether you're in high-mix prototyping or large-scale production, we can help you find the right machine for your needs.