Manual vs. NC vs. CNC Grinding Machines: What’s the Difference?

In the world of precision machining, grinding machines have evolved significantly over the past few decades. From manual (traditional) grinding to NC (Numerical Control) and now CNC (Computer Numerical Control) systems, each stage in this evolution has brought greater accuracy, efficiency, and automation. If you're considering upgrading your equipment or simply want to understand the differences, this article will guide you through the fundamentals.

Why Does the Grinding Control System Matter So Much?

The control system of a grinding machine directly impacts machining accuracy, operational stability, production efficiency, and is closely tied to the skill level required from operators and overall equipment cost. Whether you’re a factory owner, process engineer, or production supervisor, understanding the differences among these three control types will help you choose the most suitable equipment and enhance your company’s competitiveness.

1. Manual Grinding Machines

The Flexible Partner for Skilled Technicians

Features

- Feed and control are operated via manual handwheels.

- Relies heavily on the operator’s experience and tactile precision.

Advantages

- Lowest purchase cost and ideal for beginners.

- Suitable for prototyping, low-volume machining, or repair work.

- High operational flexibility for experienced technicians.

Limitations

- Labor- and skill-dependent, resulting in lower process stability.

- Cannot store programs—each setup must be redone.

- Not suitable for high-volume or high-precision production environments.

2. NC Grinding Machines

A Practical Step Toward Automation

Features

- Uses digital control with basic programming or parameter input.

- Commonly used for simple positioning or basic motion operations.

Advantages

- Easier to operate than manual machines, improving human factor consistency.

- Better machining accuracy, suitable for mid-level production needs.

- More affordable than CNC models, with moderate investment threshold.

Limitations

- Limited programmability—not ideal for complex profiles or diverse parts.

- Does not support CAD/CAM, probing systems, or advanced automation.

- Less scalable for future smart manufacturing upgrades.

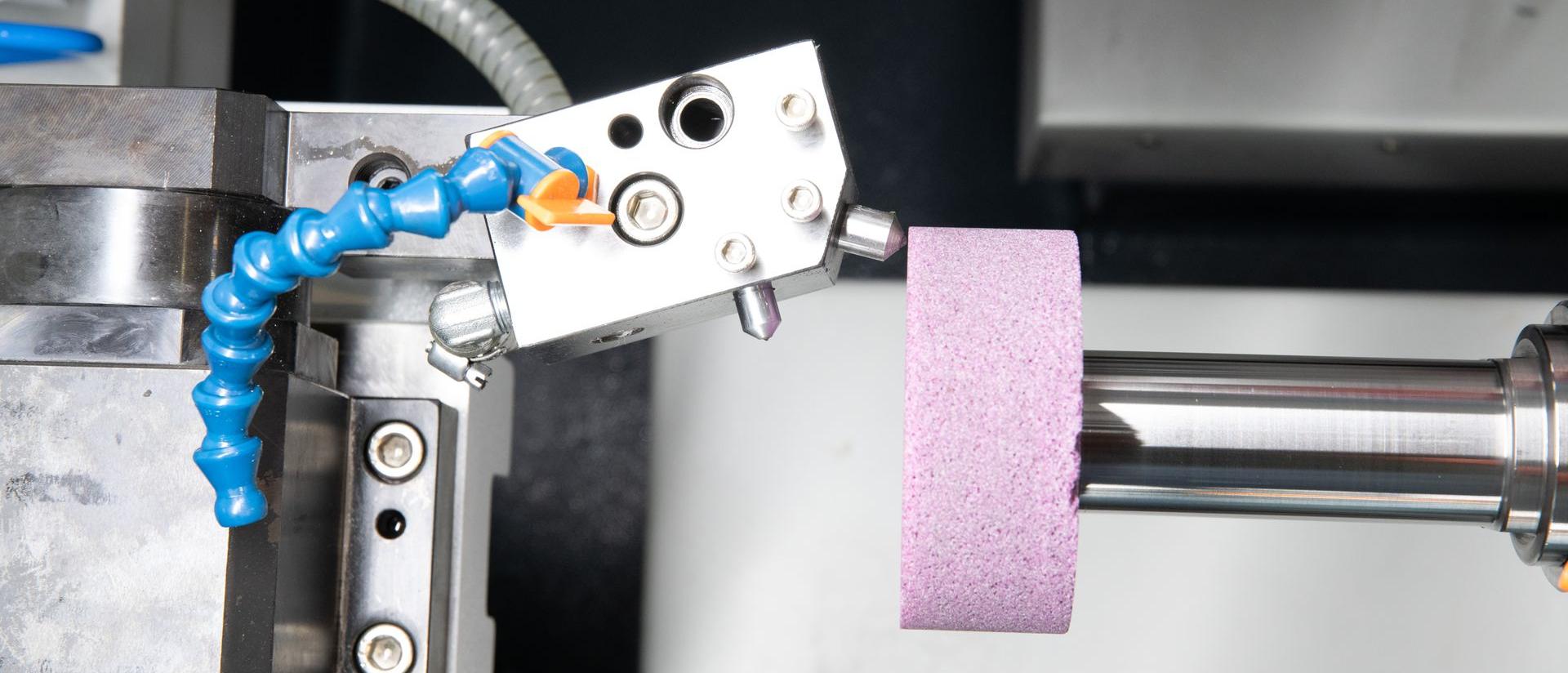

3. CNC Grinding Machines

The Mainstream Solution for High Precision and Automation

Features

- Fully equipped with computer numerical control and programmable machining paths.

- Compatible with CAD/CAM, probing systems, automatic loading/unloading, and in-process correction.

Advantages

- High consistency and repeatability in machining.

- Capable of handling complex profiles and custom shapes.

- High level of automation suitable for lights-out production.

- Supports data storage, process records, and smart manufacturing integration.

Limitations

- Higher investment in equipment and training.

- Steeper learning curve—requires programming knowledge.

- For small to medium enterprises, ROI needs to be carefully assessed.

Which Grinding Machine Should I Choose?

When selecting grinding equipment, there is no absolute “best”—only the most suitable solution for your specific needs.

Here are some tips for choosing:

01

If you focus on repair work, prototyping, or have a tight budget, manual machines may be your best bet.

02

If you need easier operation for different personnel and work with relatively simple parts, NC machines are a solid choice.

03

If you value machining quality, automation, and are planning to move toward smart manufacturing, CNC machines are the ideal investment.

e-tech's Professional Advice & Support

As a specialized grinding machine manufacturer in Taiwan, e-tech offers a comprehensive range of grinding solutions to help customers tackle all types of machining challenges. Our products and technologies include:

• Traditional surface, cylindrical, and centerless grinders

• CNC precision internal, external, vertical, surface, centerless, and profile grinders

• Multi-axis CNC compound grinding machines

• Our intuitive iGrind conversational graphic interface, designed to lower the learning curve and boost productivity

• Customized automation solutions, tailored programming, and post-process support

Whether you’re expanding your factory, replacing legacy equipment, transitioning to smart manufacturing, or seeking higher efficiency—e-tech can help you evaluate and implement the grinding solution that best fits your needs.