Vertical Grinding Machines

When it comes to machining large and heavy parts, precision and stability are critical. Vertical grinding machines have become the go-to solution for oversized parts that require tight tolerances and high surface quality. Unlike horizontal grinding, vertical grinding offers unique advantages that help manufacturers improve efficiency and product quality.

In this post, we’ll explore the benefits of vertical grinding for large parts, how it compares to other methods, and why it might be the best fit for your production needs

What Is Vertical Grinding?

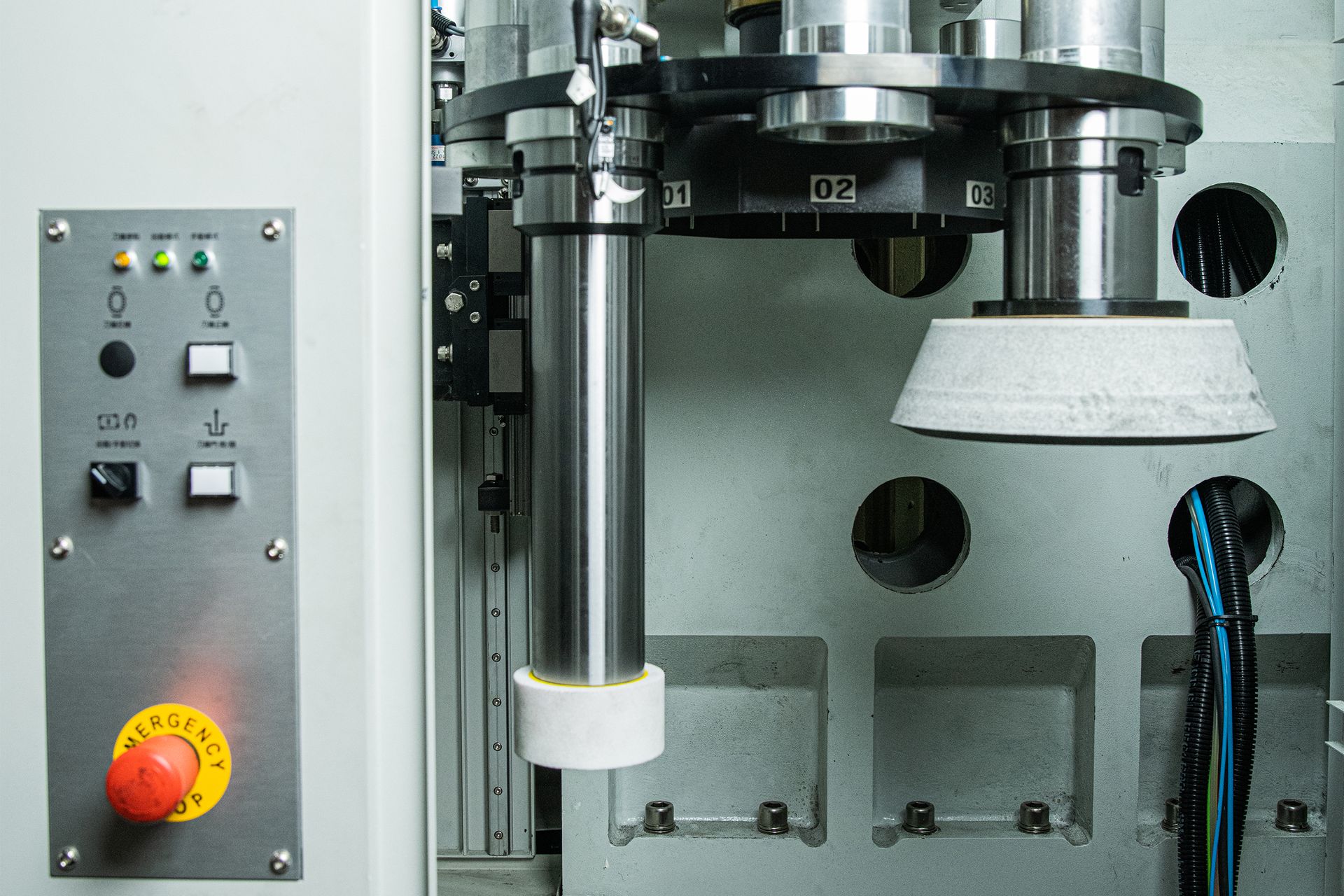

Vertical grinding is a process where the grinding wheel is mounted vertically, usually above the workpiece. The workpiece itself is typically held on a horizontal table that rotates or moves beneath the wheel. This setup is especially useful for large, heavy, or awkwardly shaped parts that are difficult to handle on horizontal grinders.

Why Vertical Grinding Works Best for Large Parts

Superior Workpiece Support and Stability

One

of the biggest challenges in grinding large parts is ensuring stable and secure

workholding. The vertical orientation allows gravity to assist in holding the

workpiece firmly against the table. This reduces vibration and improves surface

finish quality. The setup also supports heavy parts more safely, lowering the

risk of deformation during machining.

Efficient Use of Floor Space

Large parts require equally large machines, which can take up significant floor space. Vertical grinding machines often have a smaller footprint compared to horizontal grinders with similar capacity, making better use of workshop space.

Easier Loading and Unloading

Handling oversized parts can be cumbersome. Vertical grinders typically feature tables at convenient working heights, allowing for easier loading and unloading with cranes or forklifts. This reduces operator strain and improves safety.

Key Applications of Vertical Grinding Machines

Vertical grinding machines are widely used in industries where large, precision parts are common, such as:

Heavy equipment manufacturing

Grinding machine bases, engine blocks, and chassis parts

Aerospace

Large turbine components and structural parts

Energy sector

Grinding of wind turbine hubs, generator rotors, and pump housings

Automotive

Oversized transmission housings and brake drums

Vertical Grinding vs. Horizontal Grinding:

What’s the Difference?

While both vertical and horizontal grinders are designed to produce high-quality finishes, their design differences mean they excel in different scenarios.

Choosing the right machine depends on the size and complexity of the parts you need to process.

Vertical Grinding

Ideal for large, heavy, or irregularly shaped parts. It offers better stability and workpiece support, reducing distortion risks.

How Vertical Grinding Improves Production Efficiency

Thanks to stable workpiece support and efficient loading, vertical grinding machines can maintain high throughput without sacrificing quality. The vertical design also often allows easier integration with automation systems such as robotic loaders or automated pallet changers, helping reduce downtime and labor costs.

Final Thoughts

If your manufacturing process involves oversized parts that require precision grinding, vertical grinding machines are an excellent investment. They offer unmatched stability, safety, and efficiency advantages that can help you meet tight tolerances and demanding surface finish requirements.

At e-tech, we provide a full range of vertical grinding solutions made in Taiwan, engineered for durability and performance. Whether you’re handling prototypes or large-scale production, we can help you find the right machine tailored to your needs.