Introduction

In modern manufacturing, precision grinding is a vital step for achieving high-quality surface finishes and tight tolerances. Two of the most common methods are centerless grinding and cylindrical grinding. While both methods remove material from a workpiece, they do so in very different ways. Understanding these differences is key to choosing the right process for your production needs.

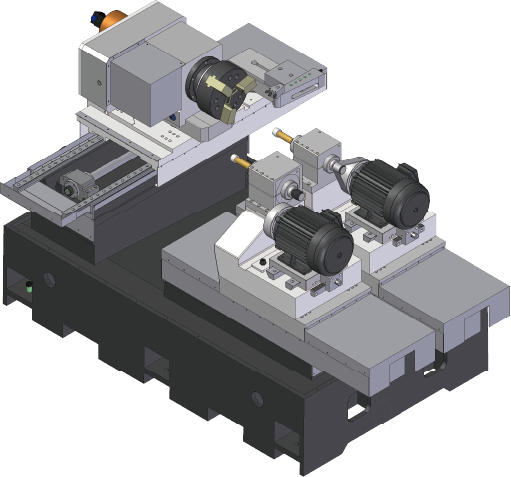

What Is Cylindrical Grinding?

Cylindrical grinding involves holding a workpiece between two centers while a rotating grinding wheel removes material from its outer surface. The part rotates as it is ground, which makes this method ideal for achieving precision roundness and tight dimensional control.

Common Uses

- Shafts and rods

- Pins and rollers

- Components with stepped or complex diameters

Benefits

- Excellent accuracy and roundness

- Suitable for parts with varying geometries

- High stability during grinding

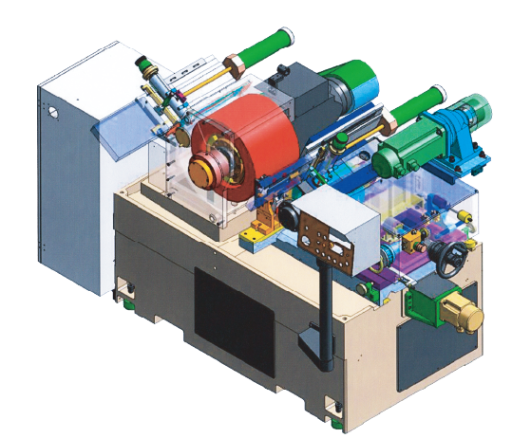

What Is Centerless Grinding?

Centerless grinding does not use centers to hold the workpiece. Instead, the part is supported between a grinding wheel, a regulating wheel, and a work rest blade. The part is rotated and fed through the machine continuously, making it ideal for fast production of simple cylindrical components.

Common Uses

- Dowel pins

- Bushings

- Straight rods and tubes

Benefits

- High-speed continuous processing

- Minimal need for clamping or repositioning

- Perfect for high-volume production

Key Differences Between the Two Methods

01 Workpiece Support

- Cylindrical grinding: requires holding the part between two centers. This allows for complex shaping and tight control.

- Centerless grinding: supports the part externally without clamping, making it better for straight and uniform parts.

02 Flexibility

- Cylindrical grinding: is more flexible and can handle multiple diameters and complex shapes.

- Centerless grinding: is optimized for speed and uniformity, best used for parts with simple, consistent profiles.

03 Setup and Efficiency

- Cylindrical grinding: is generally easier to set up for small batches or custom jobs.

- Centerless grinding: requires precise setup but delivers faster results once running, especially for large quantities.

Which Method Should You Choose?

Each method has a specific strength, and many machine shops use both depending on the application.

Choose cylindrical grinding if your part has steps, shoulders, or complex profiles.

Choose centerless grinding for long runs of uniform parts that require fast processing.

Final Thoughts

Grinding is not just about finishing. It is a critical step that determines part accuracy and performance. By understanding the differences between centerless and cylindrical grinding, manufacturers can improve efficiency, reduce waste, and deliver higher quality parts.

At e-tech, we offer a complete range of grinding solutions made in Taiwan, including cylindrical, centerless, internal, and surface grinding machines. Whether you are working on prototypes or high-volume production, we are here to help you find the right solution

Mail | info@etechtw.com

Web | www.etechtw.com

Phone | +886-4-25686418