B-Axis

When talking about CNC grinding, terms like X, Z, and Y axes are fairly straightforward. They represent linear movement—left and right, back and forth, up and down. But once you introduce a B-axis, things get a little more interesting.

If you're researching grinding machines or looking to invest in flexible equipment, understanding what the B-axis does—and how it improves grinding performance—can help you make a smarter decision.

What Is the B-Axis in Grinding?

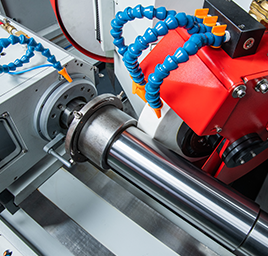

In CNC terms, the B-axis refers to rotational movement around the Y-axis. In grinding, it typically applies to machines that feature a rotating wheelhead or turret-style spindle that can pivot at precise angles.

Unlike standard grinders that have fixed wheels aligned at 0° or 90°, a B-axis allows the wheelhead to rotate—often in 1-degree or 5-degree increments, and sometimes with continuous (infinitely variable) positioning when equipped with a direct-drive (DD) motor.

This flexibility allows the grinding wheel to approach the workpiece from different angles, enabling multiple grinding operations in a single setup.

Why Is the B-Axis Important?

The B-axis isn’t just a fancy add-on. It solves several practical and productivity-related problems in modern grinding:

01 Multi-Angle Grinding

With a B-axis, the machine can switch between grinding surfaces—such as OD, face, radius, and even threads—without manual repositioning or changing the setup.

This is particularly useful for parts with:

Complex geometries

Shoulder angles and Chamfers

Combined OD/face surfaces

It’s also ideal for precision molds, gears, and aerospace components, where multiple surfaces must be ground with tight angular relationships.

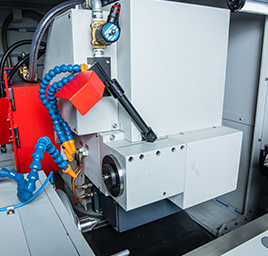

02 One Setup, Multiple Processes

In traditional setups, each surface or angle might require its own dedicated fixture or machine pass. With a programmable B-axis, the machine can rotate the wheelhead to the exact angle needed, perform the grind, then move on to the next step—all without refixturing.

This reduces:

Setup time

Fixture complexity

Cumulative error between operations

It also opens the door for automation and lights-out production, since fewer manual interventions are needed.

03 Improved Accuracy and Repeatability

B-axis mechanisms—especially those driven by direct-drive motors—offer high positioning accuracy, often within arc-seconds.

That means:

Better control over angular geometry

Improved surface finish on angled features

Tighter tolerances between multiple faces on the same part

The ability to perform compound grinding in a single operation also reduces stacked error from repeated setups.

Where You'll Find B-Axis Grinding

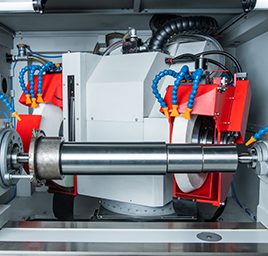

Many modern grinding machines now offer B-axis options, particularly on universal cylindrical grinders and ID/OD compound grinders. At e-tech, for example,

machines like the EGP-B series feature:

- ● ● ● ● ● Better control over angular geometry

- ● ● ● ● ● Improved surface finish on angled features

- ● ● ● ● ● Tighter tolerances between multiple faces on the same part

These systems are ideal for manufacturers working with complex part geometries or who need to maximize floor space and production efficiency.

Is a B-Axis Right for You?

A B-axis-equipped grinder may be overkill for shops focused only on high-volume, single-feature grinding. But if you're working with:

01

Complex or multi-feature parts

02

Prototyping to production flexibility

03

Tight geometric tolerances

04

Small batch, high-mix work

...then a machine with a B-axis can dramatically reduce your setup times, increase throughput, and improve overall machining flexibility.

Final Thoughts

As part geometries become more complex and customer demands increase, the ability to grind multiple features in a single setup is no longer a luxury—it’s a competitive advantage.

The B-axis opens up a new dimension of grinding: one that brings precision, flexibility, and efficiency together in one platform.

At e-tech, we design grinding solutions that help shops adapt to these challenges. Whether you're looking at B-axis universal grinders, multi-process ID/OD machines, or something more application-specific, our team is here to help you find the right fit.