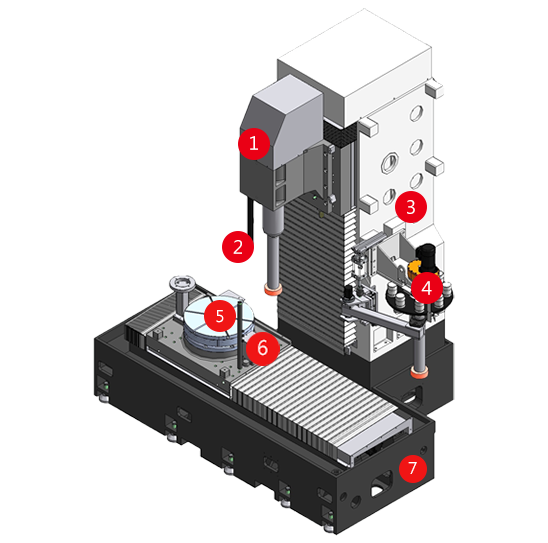

Machine Design Feature

1

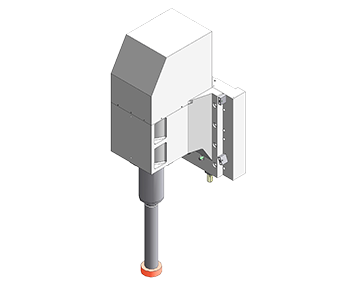

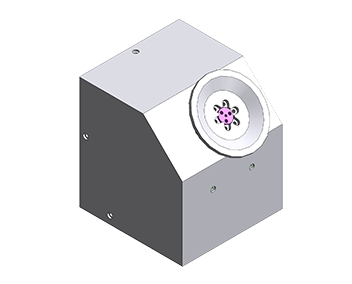

Grinding spindle

The use of a built-in motor spindle, in addition to fast cutting speed, also has the advantages of good cutting force, low vibration, high cutting rate, high precision and easy space arrangement. The spindle adopts a long nose design, which is easy for deep hole processing. The spindle can be extended into the workpiece, reducing the length of the grinding wheel handle and effectively increasing the grinding rigidity.

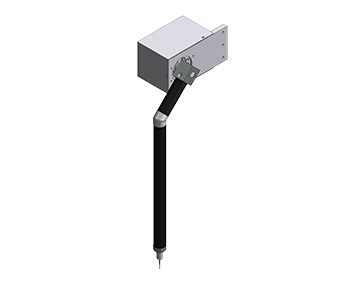

2

In-flight measurement system

e-tech Machinery specially planned the LP2 grinder's special measuring and B53 measuring mechanism and matched with the comparison ring gauge, which not only greatly increased the tool setting speed, but also re-measured after finishing the grinding to achieve the best accuracy.

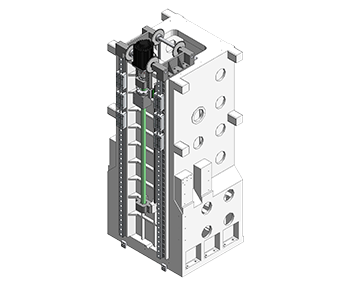

3

High precision linear slide

Each axis uses the C1 grinding grade high-precision ball screw selected by Japan NSK, which has the characteristics of high efficiency, high rigidity, high lead and predictable life.

Take the lead in major factories to use six-slot round ball linear rails, and use the configuration of extended sliders to achieve the characteristics of weight uniformity, low friction coefficient and uniform accuracy.

4

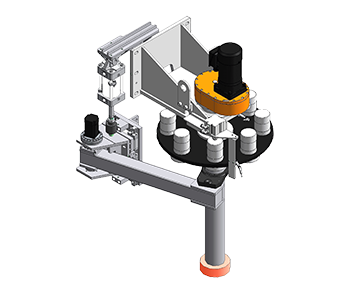

ATC automatic tool changer

The use of a hat-shaped mechanism and an ATC tool changer not only has good reliability, but also has high tool change efficiency. With 6 to 8 tool holders storage capacity planning, complex workpieces or applications that require the best surface roughness can be implemented.

5

Hydrostatic pressure turntable

The turntable uses a hydrostatic design with zero metal contact, which can maintain a long life and bring a high degree of accuracy guarantee (rotation accuracy 0.001mm).

High rigidity design and ultra-high load capacity, dead load up to 1200 kg.

6

Diamond roller sand repair seat

Diamond rollers are specially selected for sand repairing, which is different from diamond sanding pens. The diamond rollers are not easy to wear and have the characteristics of high shape accuracy and high repairing efficiency.

7

Ultra-rigid home structure

The low-profile mechanical structure, combined with the high-rigidity design of the machine, and the one-sided water flow design that considers the stable heat source between the two shafts, not only facilitates the discharge of cutting debris, but also keeps the machine clean and minimizes the impact on temperature changes.

Applications

Explore by industry to discover which types of workpieces are supported by e-tech’s grinding solutions.

Grinding Sample

Specification

| EGV-600CNC | EGV-800CNC | |

| Max. ID Grinding Diameter | ∅70~∅550 mm | ∅70~∅750 mm |

| Max. OD Grinding Diameter | ∅600 mm | ∅800 mm |

| Max. ID/OD Grinding Length | 550 mm | 550 mm |

| Max. Swing Diameter | ∅600 rpm | ∅800 rpm |

| Max. Workpiece Weight | 800 kgs | 800 kgs |

| Spindle Speed | 10000 rpm | 10000 rpm |

| Tool Holder Interface | HSK-A100 | HSK-A100 |

| Table Size | ∅600 mm | ∅800 mm |

| Max. Swiveling Speed | 200 rpm | 200 rpm |

| Max. Grinding Wheel | ∅250 mm | ∅250 mm |

| Max. Grinding Grinding Wheel Wheel Capacity Weight | 8 kgs | 8 kgs |

| Grinder Wheel Capacity | 8(Hydrostatic pressure) | 8(Hydrostatic pressure) |

Learn More About Our Product

For more detailed information, please download our catalog. The catalog includes standard accessories, optional accessories, and a comprehensive specification guide to help you better understand our product’s features!