Facing unprecedented pressure and challenges from the U.S. reciprocal tariff policy, Taiwan’s manufacturing industry is under strain. e -tech Machinery is proactively responding with smart manufacturing and resilient sustainability strategies, showcasing outstanding competitiveness and industry leadership.

As Taiwan’s leading precision grinding machine

manufacturer, e -tech has long focused on the research and production of

high-precision grinders, including cylindrical, internal/external, vertical,

surface, centerless, and multi-functional grinding machines. These are widely

applied in advanced industries such as aerospace, automotive, and precision

bearings. In recent years, the company has actively embraced Industry 4.0

concepts, integrating automation, smart connectivity, and AI algorithms into

grinding processes to create a comprehensive “Smart Grinding Solution.”

Through real-time measurement and automatic

compensation functions, machines can autonomously assess machining conditions

and make precise adjustments, reducing reliance on manual intervention while

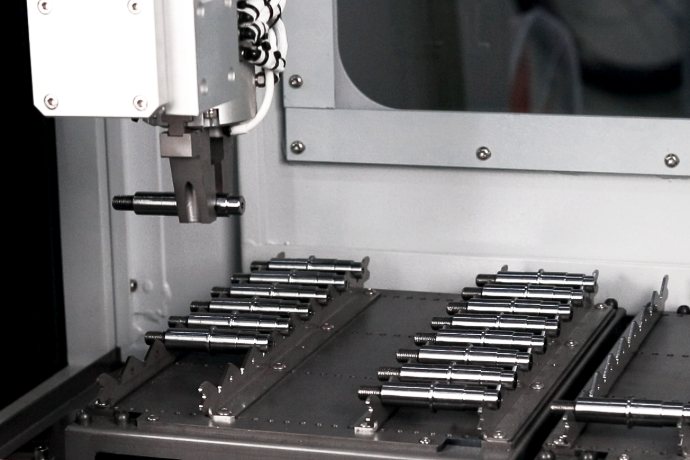

improving product yield and production efficiency. In automation, e-tech

collaborates with robotic system integrators to develop modular automatic

loading/unloading systems and production line integration planning, achieving

“one operator, multiple machines” and highly flexible, efficient production

models.

“Grinding machines are not just processing

equipment, but an integral part of the smart manufacturing ecosystem,” e-tech

emphasizes. Looking ahead, the company will continue investing in AI-driven

process optimization and work hand-in-hand with global partners. Amid shocks

and transformation, e-tech consistently incorporates ESG into decision-making,

avoiding short-term gains at the expense of long-term sustainable value.

Through technological innovation, the company not only adapts to market changes

but also creates positive economic and environmental impacts. At the same time,

by strengthening connections with employees, communities, and suppliers, e-tech

reduces resistance during transformation and gains broader support.

e-tech Machinery’s Mini Genie automated robotic arm for loading and unloading applications.

With Taiwan as its R&D and manufacturing hub, e-tech has expanded its market to 25 countries worldwide. Confronting tariff challenges and global market uncertainties, the company enhances organizational resilience through technological upgrades and sustainability strategies, building long-term competitive advantages and highlighting the resilience and innovative spirit of Taiwan’s manufacturing industry.

In

the future, e-tech Machinery will continue to deepen its smart grinding

technologies, providing more efficient and sustainable solutions for global

manufacturing.