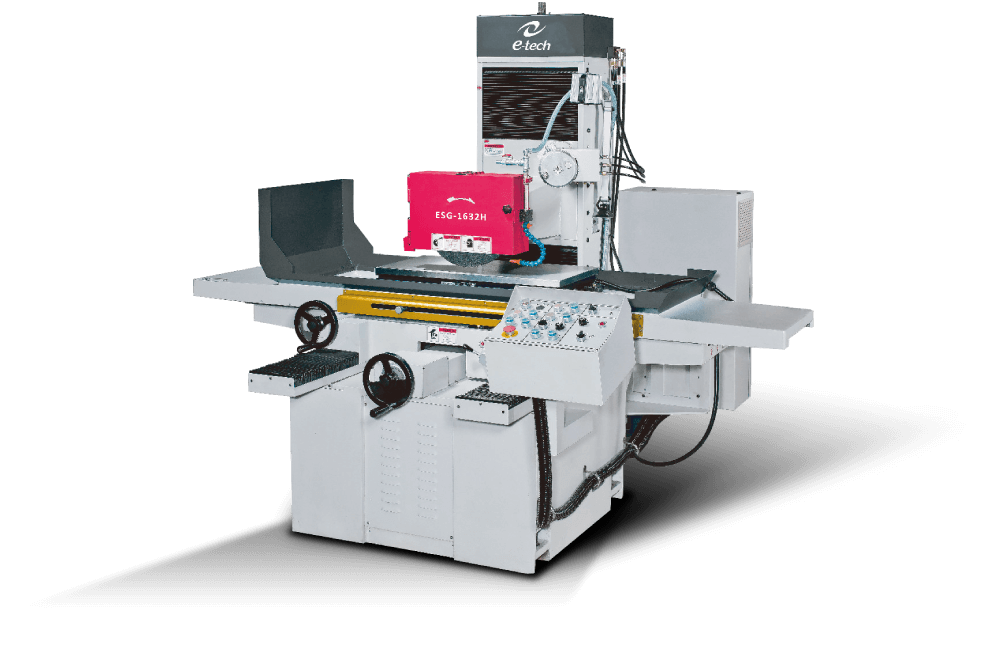

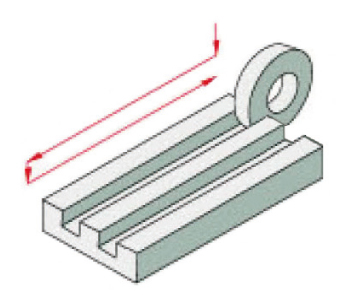

Grinding Cycle

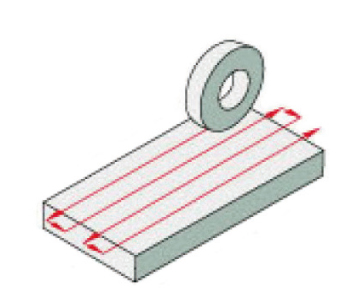

1. Step grinding

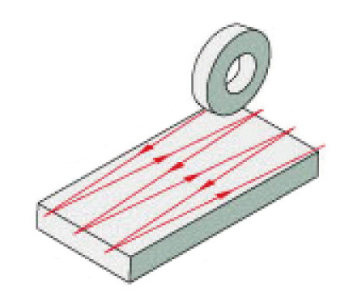

2. Criss-cross grinding

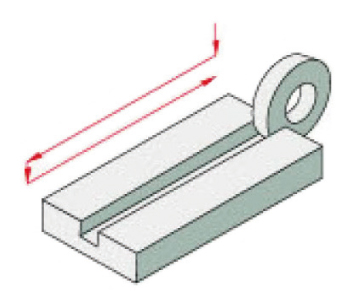

3. Plunge grinding

4. Multiple gouges grinding (opt.)

A Type Control Panel

The machine is equipped with a PLC control, a color touch screen and a user-friendly interface. The operator can simply set up the grinding amount and start a new grinding cycle. The last grindingcycle setting willbe saved automatically and can be easily repeated by simply pressing the "Cycle start" buttom

Specification

| Compare ESG-618M |

Compare ESG-618H |

Compare ESG-618A |

Compare ESG-820M |

Compare ESG-820H |

Compare ESG-820A |

Compare ESG-1224M |

Compare ESG-1224H |

Compare ESG-1224A |

Compare ESG-1632M |

Compare ESG-1632H |

Compare ESG-1632A |

Compare ESG-2040NC |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| General Capacity | Table size | mm | 150x460 | 150x460 | 150x460 | 200x510 | 200x510 | 200x510 | 300x600 | 300x600 | 300x600 | 400x800 | 400x800 | 400x800 | 500x1050 | |

| Max. grinding length | mm | 475 | 475 | 475 | 600 | 600 | 600 | 650 | 650 | 650 | 850 | 850 | 850 | 1050 | ||

| Max. grinding width | mm | 160 | 160 | 160 | 220 | 220 | 220 | 310 | 310 | 310 | 410 | 410 | 410 | 500 | ||

| Distance from table surface to spindle centerline | mm | 400 | 400 | 400 | 400 | 400 | 400 | 510 | 510 | 510 | 510 | 510 | 510 | 600/700(opt.) | ||

| Max. table load (inch chuck) | kg | 150 | 150 | 150 | 280 | 280 | 280 | 400 | 400 | 400 | 580 | 580 | 580 | 800 | ||

| Standard magnetic chuck size | mm | 150x450 | 150x450 | 150x450 | 200x500 | 200x500 | 200x500 | 300x600 | 300x600 | 300x600 | 400x800 | 400x800 | 400x800 | 500x1000 | ||

| Grinding Wheel | Diameter x Width x Bore | mm | Ø180x13xØ31.75 | Ø180x13xØ31.75 | Ø180x13xØ31.75 | Ø180x13xØ31.75 | Ø180x13xØ31.75 | Ø180x13xØ31.75 | Ø305x31xØ76 | Ø305x31xØ76 | Ø305x31xØ76 | Ø355x50xØ127 | Ø355x50xØ127 | Ø355x50xØ127 | Ø355x38xØ127 | |

| Spindle speed (60HZ/50HZ) | rpm | 3000/3600 | 3000/3600 | 3000/3600 | 3000/3600 | 3000/3600 | 3000/3600 | 1425/1710 | 1425/1710 | 1425/1710 | 1425/1710 | 1425/1710 | 1425/1710 | 1450/1750 | ||

| X axis | Manual travel | mm | 485 | 485 | 485 | 600 | 600 | 600 | 710 | 710 | 710 | 960 | 960 | 960 | 1150 | |

| Hydraulic Travel | mm | - | 485 | 485 | 510 | 510 | 510 | 650 | 650 | 650 | 920 | 920 | 920 | 1100 | ||

| Table speed (Infinite variable speed) | m/min | - | 1-25 | 1-25 | 1-25 | 1-25 | 1-25 | 3-25 | 3-25 | 3-25 | 3-25 | 3-25 | 3-25 | 3-25 | ||

| Y axis | Feed rapid (approx.) | mm/min | - | - | 230 | - | - | 230 | 190 | 190 | 190 | 190 | 190 | 190 | 500 | |

| Automatic traverse increment | mm | - | - | 0.001-0.099 | - | - | - | 0.002/0.006/0.01 | 0.002/0.006/0.01 | 0.001-0.099 | 0.002/0.006/0.01 | 0.002/0.006/0.01 | 0.001-0.099 | 0.001-0.999 | ||

| Handwheel per graduation | mm | 0.005 | 0.005 | 0.001mm/MPG | 0.005 | 0.005 | 0.001mm/MPG | 0.002 | 0.002 | 0.002 | 0.001 | 0.001 | 0.001 | 0.001mm/MPG | ||

| Handwheel per revolution | mm | 1 | 1 | 0.1mm/MPG | 1 | 1 | 0.1mm/MPG | 0.2 | 0.2 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1mm/MPG | ||

| Z axis | Manual travel | mm | 180 | 180 | 180 | 230 | 230 | 230 | 330 | 330 | 330 | 430 | 430 | 430 | 575 | |

| Feed rapid (approx.) | mm/min | 650 | 650 | 650 | 650 | 650 | 650 | 960 | 960 | 960 | 1200 | 1200 | 1200 | 1000 | ||

| Automatic traverse increment | mm/min | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-10 | 0.5-8 | 0.5-8 | 0.5-8 | 0.5-8 | 0.5-8 | 0.5-8 | 1-20 | ||

| Handwheel per graduation | mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | ||

| Handwheel per revolution | mm | 5 | 5 | 5 | 5 | 5 | 5 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | ||

| Motor | Spindle motor | HP | 1.5HP/3HP (opt.) | 1.5HP/3HP (opt.) | 1.5HP/3HP (opt.) | 2HP/3HP(opt.) | 2HP/3HP(opt.) | 2HP/3HP(opt.) | 3HP | 3HP | 3HP | 5HP | 5HP | 5HP | 7.5HP/10HP (opt.) | |

| Crossfeed Z axis motor | - | 25W | 25W | 40W | 40W | 40W | 1/4HP | 1/4HP | 1/4HP | 1/4HP | 1/4HP | 1/4HP | 1/4HP | |||

| Elevating Y axis motor | - | 40W | 40W | 40W | 40W | 40W | 1/4HP | 1/4HP | 1/4HP | 1/4HP | 1/4HP | 1/4HP | 1KW | |||

| Hydraulic motor | Kw | - | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | ||

| Machine | Net weight | kg | 910 | 910 | 910 | 1470 | 1470 | 1470 | 1750 | 1750 | 1750 | 3500 | 3500 | 3500 | 5900 | |

| Gross weight | kg | 1040 | 1040 | 1040 | 1620 | 1620 | 1620 | 2050 | 2050 | 2050 | 3800 | 3800 | 3800 | 6900 | ||

| Packing size (L x W x H) | mm | 1560x1300x2200 | 1560x1300x2200 | 1560x1300x2200 | 1780x1600x2200 | 1780x1600x2200 | 1780x1600x2200 | 1970x2250x2250 | 1970x2250x2250 | 1970x2250x2250 | 2730x2250x2250 | 2730x2250x2250 | 2730x2250x2250 | 3600x2230x2280 | ||

| Total space required (LxWxH) | mm | 1940x2050x1933 | 1940x2050x1933 | 1940x2050x1933 | 2123x2046x2208 | 2123x2046x2208 | 2123x2046x2208 | 4000x2700x2550 | 4000x2700x2550 | 4000x2700x2550 | 4000x2700x2550 | 4000x2700x2550 | 4000x2700x2550 | 4360x2865x2657 | ||

Standard accessories

| Leveling screws with blocks |

| Balancing stand with arbor |

| Wheel extractor |

| Operation manual with part list |

| Tools and tool box |

| Diamond Dresser&seat |

| Splash guard |

| Standard coolant tank |

| PLC control panel with color touch screen |

| Ballscrew with Servo motor for crossfeed |

| Standard grinding wheel with flange |

| Working light |

Optional accessories

| Chiller |

| Rotary table |

| Demagnetizer (Standard) |

| Coolant system w/magnetic separator |

| Angle dressing attachment |

| Radius dressing attachment |

| Parallel dressing attachment (Manual) |

| Demagnetizer (Hi-Power) |

| Electromagnetic chuck (fine pole) |

| Scope type dressing attachment |

| Dual sides dressing attachment |

| Roller type balancing stand |

| Coolant system w/magnetic separator and paper filter |

| Automatic dressing attachment with compensation system |

| Permanent magnetic chuck |

| Tilting permanent magnetic chuck |

| Coolant and dust collector |

| Dust collector |

| Hydraulic parallel dressing attachment |

| Full-enclosed splash guard |

| Oil and mist separator |

| Spare wheel flange (5”) |

| Inverter for wheel head spindle |

| Auto demagnetizer |

| Manual demagnetizer |

| Optical scale |