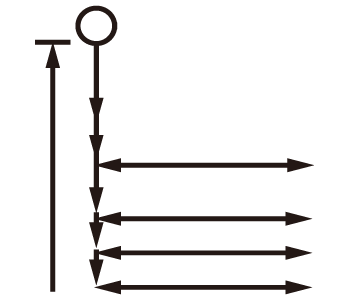

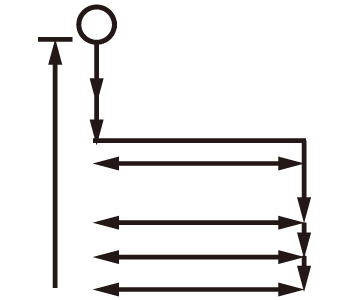

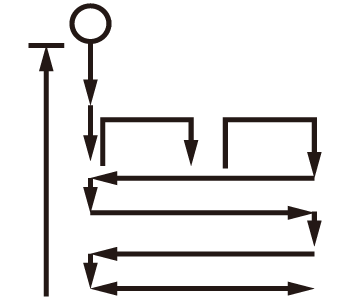

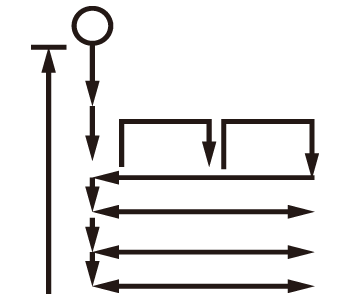

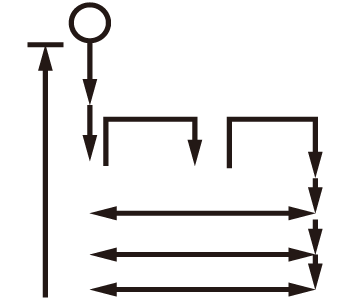

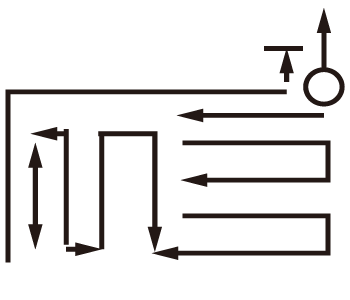

Grinding Cycle

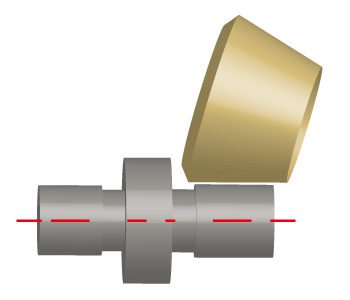

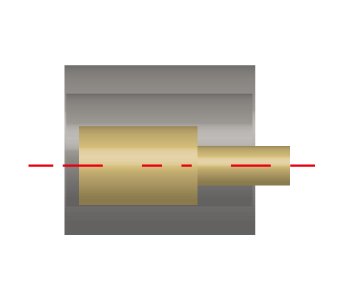

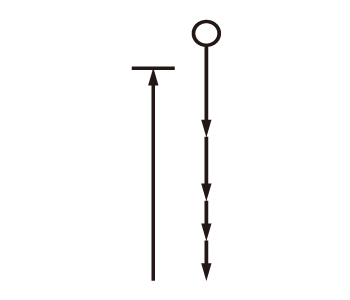

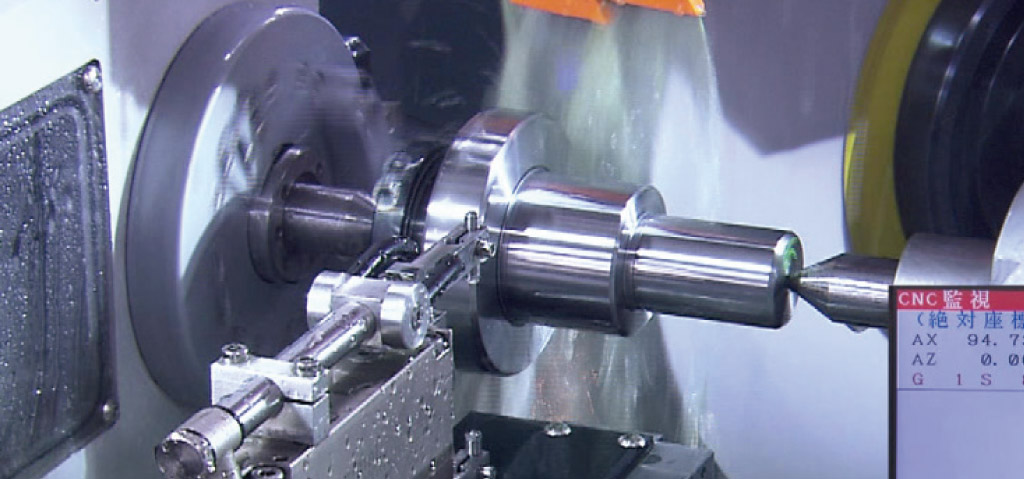

1. Plunge grinding

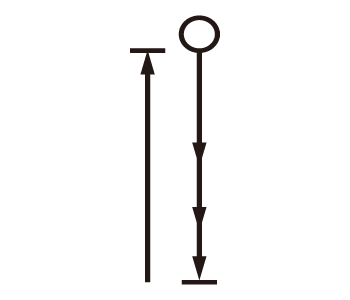

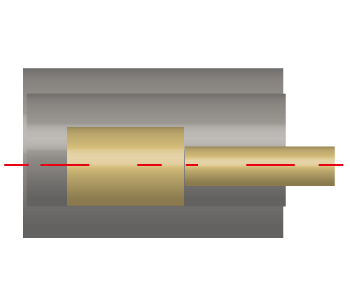

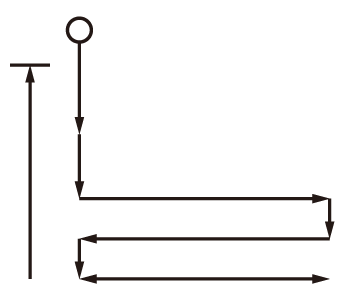

2. Traverse grinding

Both sides feed

LHS feed

RHS feed

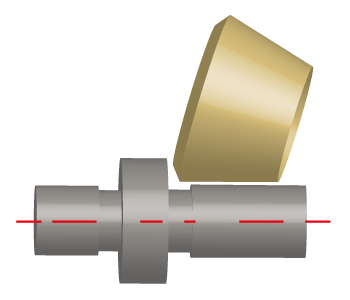

3. Plunge

Both sides feed

LHS feed

RHS feed

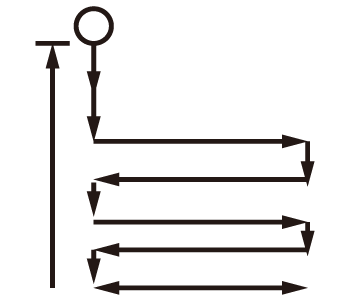

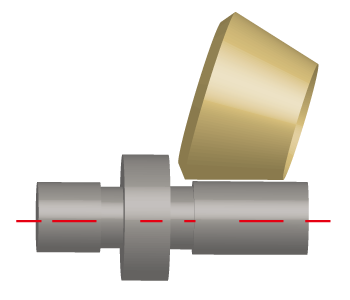

4. OD +End Face Grinding

ID Grinding Cycle (using OD Grinding Cycle)

1. Plunge

2. Traverse

iGrind Operation

Graphic Conversational Program Functions :

- OD Grinding / End Face Grinding / Form Grinding

- Form Dressing w/ Auto Compensation

- Multiple Section Grinding Sequences

- Setup Parameter Storage

- Graphic Parameter Instruction

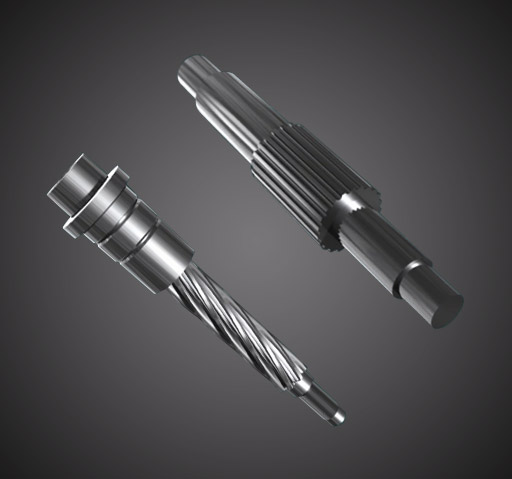

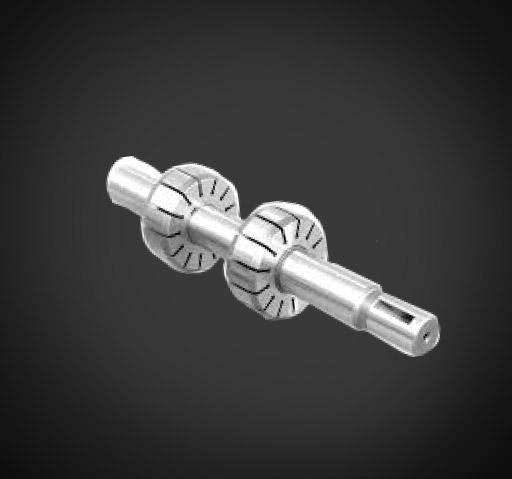

Grinding Sample

| Compare EGA- 3260 |

Compare EGA- 32100 |

Compare EGA- 32150 |

Compare EGA- 32200 |

Compare EGA- 3860 |

Compare EGA- 38100 |

Compare EGA- 38150 |

Compare EGA- 38200 |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grinding Capacity | Swing over table | mm | Ø320 | Ø320 | Ø320 | Ø320 | Ø380 | Ø380 | Ø380 | Ø380 | |

| Distance between centers | mm | 600 | 1000 | 1500 | 2000 | 600 | 1000 | 1500 | 2000 | ||

| Max. grinding daimeter | mm | Ø300 | Ø300 | Ø300 | Ø300 | Ø360 | Ø360 | Ø360 | Ø360 | ||

| Max. grinding length - dresser on workhead side | mm | 450 | 850 | 1350 | 1850 | 450 | 850 | 1350 | 1850 | ||

| Max. grinding length - dresser on tailstock side (Opt.) | mm | 600 | 1000 | 1500 | 2000 | 600 | 1000 | 1500 | 2000 | ||

| Max. load held between center | kg | 150 | 150 | 150 | 250 | 150 | 150 | 150 | 250 | ||

| Center distance between spindle & slide table | mm | 162 | 162 | 162 | 162 | 192 | 192 | 192 | 192 | ||

| Grinding Wheel | Infeed angle | deg | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Diameter x Width x Bore | mm | Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

Ø510x50-100xØ152.4 (6") Opt. Ø610x50~100xØ203.2 (8") |

||

| Motor rated power / max. torque | Kw/Nm | 7.5kw/49Nm (Opt.11Kw/ 71Nm) |

7.5kw/49Nm (Opt.11Kw/ 71Nm) |

7.5kw/49Nm (Opt.11Kw/ 71Nm) |

7.5kw/49Nm (Opt.11Kw/ 71Nm) |

7.5kw/49Nm (Opt.11Kw/ 71Nm) |

7.5kw/49Nm (Opt.11Kw/ 71Nm) |

7.5kw/49Nm (Opt.11Kw/ 71Nm) |

7.5kw/49Nm (Opt.11Kw/ 71Nm) |

||

| Wheel speed | rpm | 1250 (Opt.1650) | 1250 (Opt.1650) | 1250 (Opt.1650) | 1250 (Opt.1650) | 1250 (Opt.1650) | 1250 (Opt.1650) | 1250 (Opt.1650) | 1250 (Opt.1650) | ||

| Workhead | Max. manual swiveling angle | deg | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | |

| Spindle speed (infinite variable) | rpm | 10~600 (infinite variable) | 10~600 (infinite variable) | 10~600 (infinite variable) | 10~600 (infinite variable) | 10~600 (infinite variable) | 10~600 (infinite variable) | 10~600 (infinite variable) | 10~600 (infinite variable) | ||

| Motor rated power / max. torque | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | ||

| Center taper | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | |||

| Center working | Fixed or Rotary | Fixed or Rotary | Fixed or Rotary | Fixed or Rotary | Fixed or Rotary | Fixed or Rotary | Fixed or Rotary | Fixed or Rotary | |||

| Diameter of bore | mm | Ø26 | Ø26 | Ø26 | Ø26 | Ø26 | Ø26 | Ø26 | Ø26 | ||

| Tailstock | Tailstock quill travel | mm | 25 (Opt.50/75) | 25 (Opt.50/75) | 25 (Opt.50/75) | 25 (Opt.50/75) | 25 (Opt.50/75) | 25 (Opt.50/75) | 25 (Opt.50/75) | 25 (Opt.50/75) | |

| Cente taper | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | MT4 (Opt. MT5) | |||

| X axis | Travel | mm | 280 | 280 | 280 | 280 | 280 | 280 | 280 | 280 | |

| Max. rapid feedrate | m/min | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | ||

| Heidenhain linear scale resolution | um | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | ||

| Min. increment | mm | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | ||

| Servo motor rated power | Kw | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | ||

| Z axis | Travel | mm | 900 | 1300 | 1950 | 2450 | 900 | 1300 | 1950 | 2450 | |

| Swiveling angle | deg | ±9 | ±7 | ±5 | ±5 | ±9 | ±7 | ±5 | ±5 | ||

| Max. rapid feedrate | m/min | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | ||

| Min. increment | mm | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | ||

| Servo motor rated power | kw | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 2.5(F)/3.5(M) | 1.8(F)/2.2(M) | 1.8(F)/2.2(M) | 2.5(F)/3.5(M) | 2.5(F)/3.5(M) | ||

| Motor | Hydraulic motor | Kw | 0.38 | 0.38 | 0.38 | 0.38 | 0.38 | 0.38 | 0.38 | 0.38 | |

| Hydrodynamic GW spindle lubrication pump | kw | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | ||

| Guide way lubrication pump | kw | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | ||

| Coolant pump | Kw | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | ||

| Machine | Net Weight (semi-enclosed splash guard) | kg | 5600 | 5800 | 6300 | 6700 | 5600 | 5800 | 6300 | 6700 | |

| Gross weight | kg | 6420 | 7500 | 7800 | 8200 | 6420 | 7500 | 7800 | 8200 | ||

Standard accessories

| Infinite variable workhead w/servo motor |

| Diamond Dresser and Stand |

| Automatic wheel speed change (15 steps) |

| Carbide tip center |

| X Axis Heidenhain linear scale (resolution 0.05 um) |

| Levelling bolts and blocks |

| Operation manual and part lists |

| Fanuc CNC Controller (Oi TF) |

| Grinding Wheel + Wheel Flange |

| Standard oil cooler (cooling fan) |

| Standard coolant tank 140L |

| MPG handwheel 2 Axes control |

| Touch probe (for EGA series only) |

| LED working light |

| Tools and Tool Box |

| Electricity cabinet w/ heat exchanger |

| Semi-enclosed splash guard |

| Wheel Extractor |

| 4-color indication signal light |

| Electrical wiring diagram |

Optional accessories

| BS VM25 Integration system (OD gauging+ crash & gap control + dynamic balance system) |

| BS VM15 Integration system (OD gauging+ crash & gap control) |

| Hydraulic tailstock (w/ foot pedal) |

| Z Axis Heidenhain linear scale (resolution 0.05 um) |

| Manual grinding wheel balance system (vibrator) |

| Grinding wheel dynamic balance system |

| Wheel spindle lubrication oil cooler for hydrodynamic spindle |

| Gap & crash control device |

| Safety door lock |

| Workhead spindle adjustment arbor |

| Auto gauging device |

| Coolant system with magnetic separator & paper filter |

| Coolant system with magnetic separator |

| Coolant system with paper filter |

| Oil & mist collecting system |

| Spare grinding wheel flange |

| Full-Carbide center tip |

| FANUC 0i-TF iGrind program |

| Mitsubishi controller (M80) iGrind program |

| Electrical cabinet air conditioner |

| Interanl grinding attachment (for EGP series only) |

| Workhead upgrade to MT5 (not suitable for 25 series) |

| Tailstock upgrade to MT5 (not suitable for 25 series) |

| Roller type balancing stand/ arbor |

| Automatic 3-jaw hydraulic chuck |

| CE standard electrical cabinet |

| Touch probe |

| Transformer |

| Workpiece carrier |

| Full-enclosed splash guard |

| Workpiece supporting seat, 2pc / set |

| 2 Point Steady Rest |

| 3-point steady rest |

| 3-jaw scroll chuck |

| 4-jaw scroll chuck |

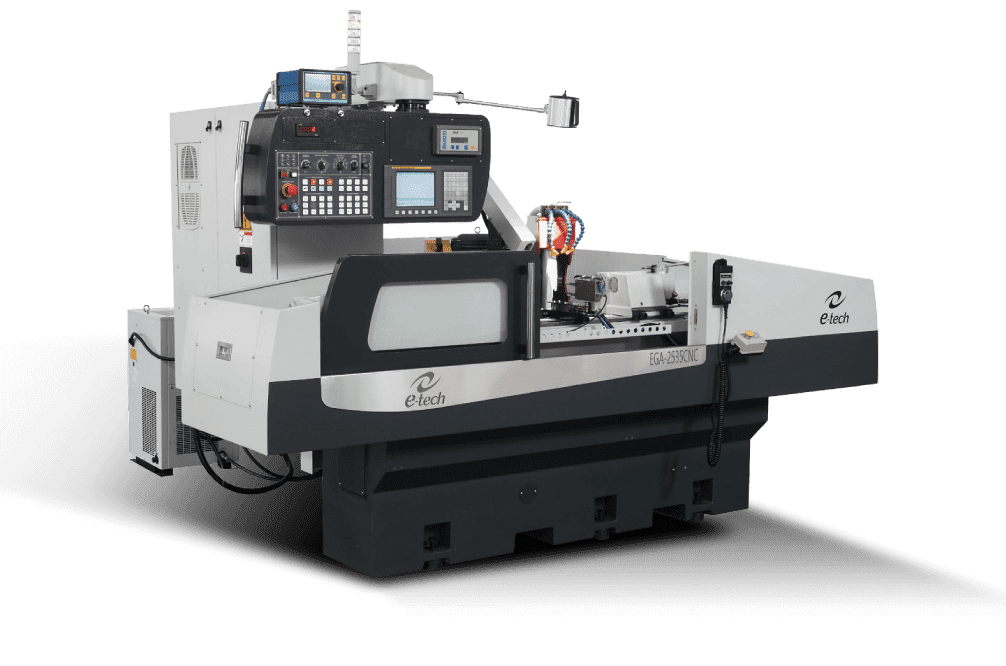

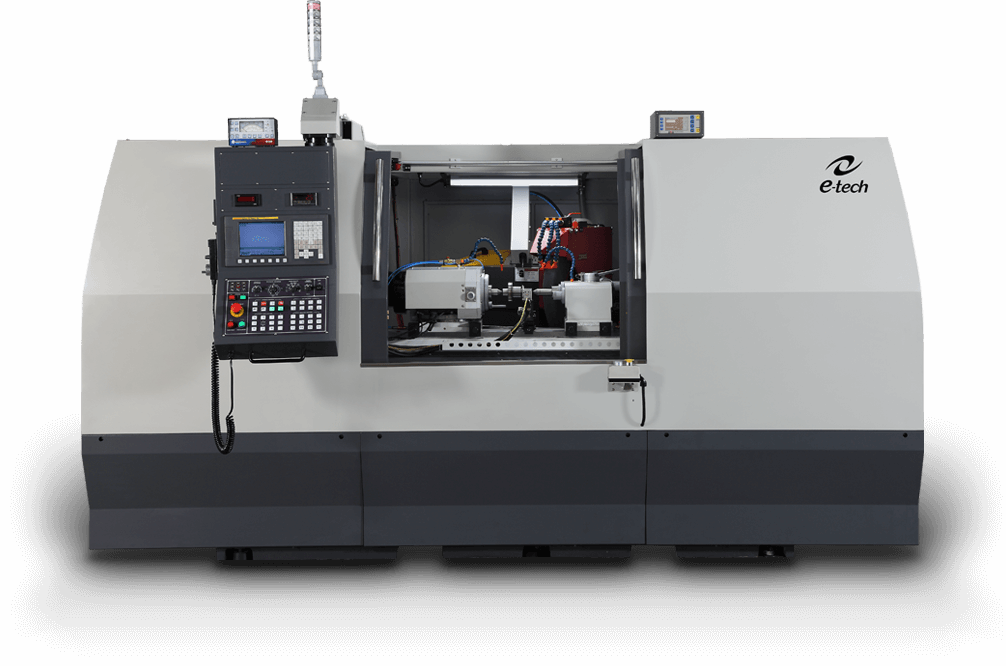

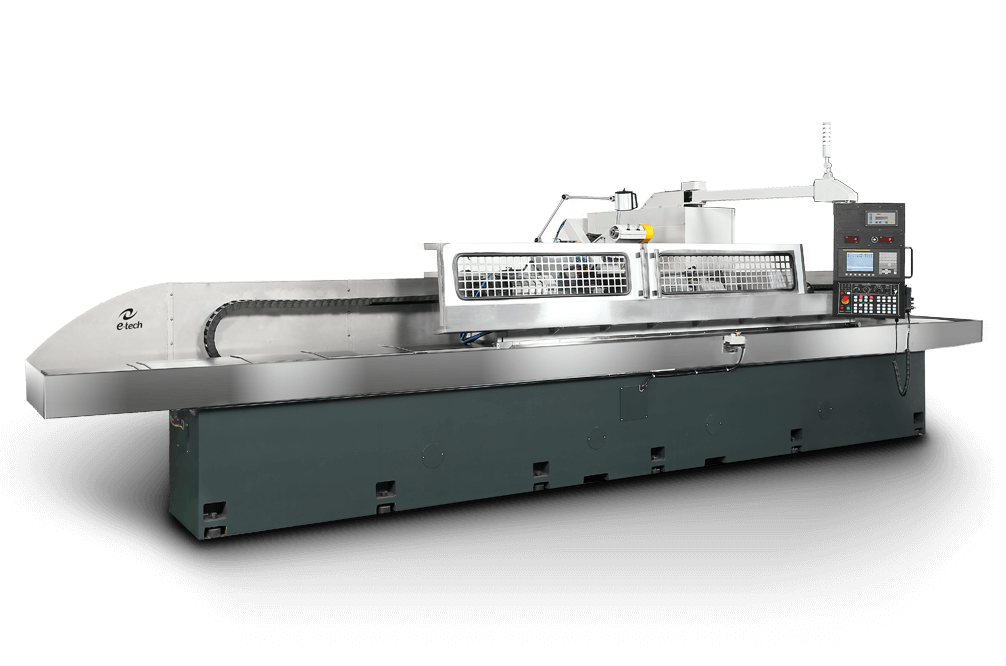

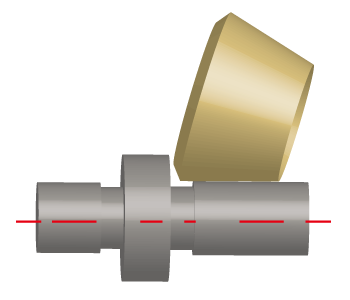

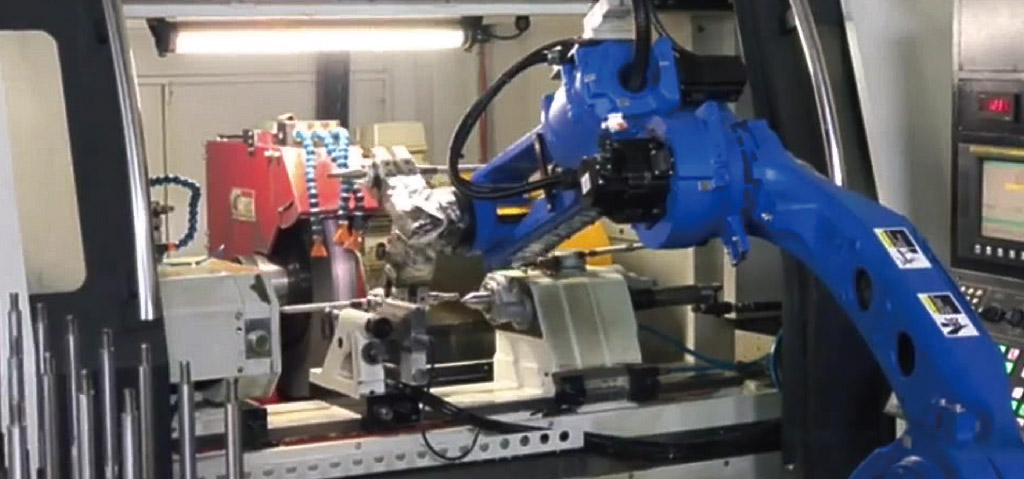

e-tech Machinery Inc. introduces EGP & EGA Series CNC cylindrical grinders with superb grinding capabilities and choice of control options. The customers’ requirements can be met with a choice of many machine options such as a touch probe, automatic sizing device, or swing down ID grinding attachment. The complete product line offers a wide range of between center distances and center heights in both plunge and angular wheelhead designs. Automation and turnkey solutions can be offered as optional equipment.

CNC Controller

- A selection of CNC control systems including Fanuc, Mitsubishi, Siemens, PC-BASE are available.

- For small and medium size workpiece grinding operations, e-tech incorporates the iGrind graphic conversational programming software.