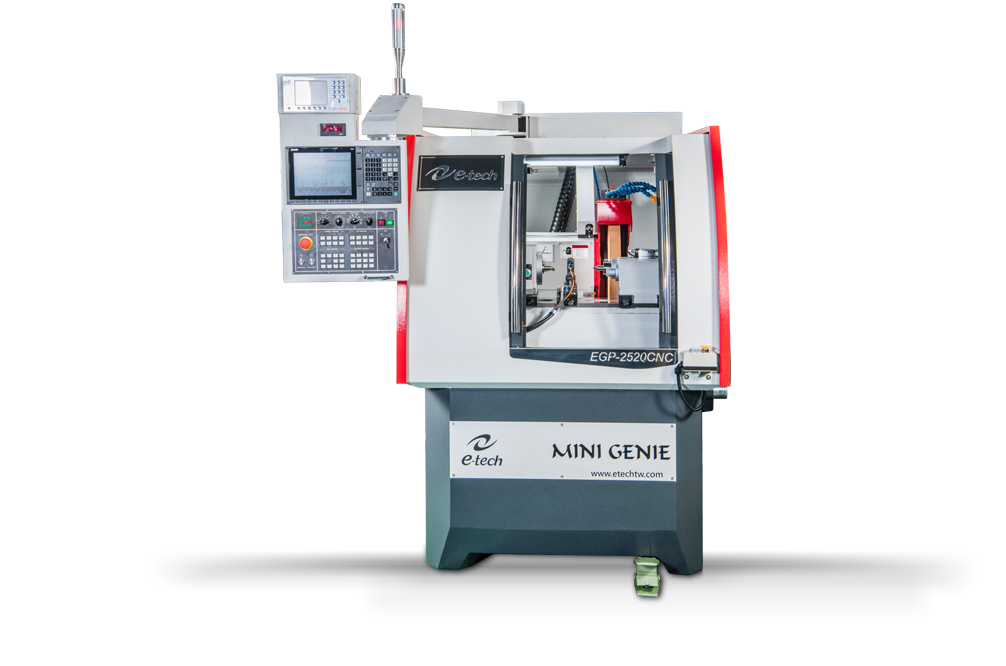

Machine Design Feature

Specification

| Compare EGP-2520 |

||||

|---|---|---|---|---|

| Grinding Capacity | Swing over table | mm | Ø250 | |

| Distance between centers | mm | 200 | ||

| Max. grinding daimeter | mm | Ø230 | ||

| Center distance between spindle & slide table | mm | 130 | ||

| Max. load held between center | kg | 20 | ||

| Grinding Wheel | Diameter x Width x Bore | mm | Ø510×50×Ø152.4 | |

| Motor rated power / max. torque | Kw/Nm | 5.5/27.6 | ||

| Wheel speed | rpm | 1250 (Opt. 1650) | ||

| Spindle type | bearing spindle | |||

| Wheel head angle | deg | 0 or 20 | ||

| Workhead | Max. manual swiveling angle | deg | 90 | |

| Spindle speed (infinite variable) | rpm | 10 ~ 600 | ||

| Motor rated power / max. torque | kw | 0.75 | ||

| Center working | Fixed or Rotary | |||

| Diameter of bore | mm | Ø20 | ||

| Center taper | MT3 (Opt. MT4) | |||

| Tailstock | Tailstock quill travel | mm | 25 | |

| Cente taper | MT3 (Opt. MT4) | |||

| Micro-taper adjustment | mm | ±0.04 | ||

| X axis | Travel | mm | 200 | |

| Max. rapid feedrate | m/min | 6 | ||

| Heidenhain linear scale resolution | um | 0.05 | ||

| Min. increment | mm | 0.0001 | ||

| Servo motor rated power | Kw | 1.2(F) / 1.5(M) | ||

| Guide way | linear way | |||

| Z axis | Travel | mm | 270 | |

| Swiveling angle | deg | 0 | ||

| Max. rapid feedrate | m/min | 8 | ||

| Min. increment | mm | 0.0001 | ||

| Servo motor rated power | kw | 1.2(F) / 1.5(M) | ||

| Guide way | linear way | |||

| Motor | Hydraulic motor | Kw | 0.38 | |

| Coolant pump | Kw | 0.2 | ||

| Machine | Net weight | kg | 2500 | |

| Measurement | mm | 1200 x 2000 x 1800 | ||

Standard accessories

| Infinite variable workhead w/servo motor |

| Fanuc CNC Controller (0i TF) / (Opt. Mitsubishi M80) |

| Carbide center tip (MT3/C10) |

| Diamond Dresser and Stand |

| Automatic wheel speed change (15 steps) |

| X Axis Heidenhain linear scale (resolution 0.05 um) |

| Levelling bolts and blocks |

| Operation manual and part lists |

| Grinding Wheel + Wheel Flange |

| Full-enclosed splash guard |

| Standard coolant tank 140L |

| MPG handwheel 2 Axes control |

| Auto lubrication system |

| Roller type balancing stand/arbor |

| LED working light |

| Tools and Tool Box |

| Electricity cabinet w/ heat exchanger |

| Wheel extractor |

| 4-color indication signal light |

| Electrical wiring diagram |

Optional accessories

| FANUC 0i-TF iGrind program |

| Mitsubishi controller (M80) iGrind program |

| Electrical cabinet air conditioner |

| Work head upgrade to MT4 |

| Tailstock upgrade to MT4 |

| Roller type balancing stand/ arbor |

| CE standard electrical cabinet |

| Automation with robot arm |

| Touch probe |

| Transformer |

| Workpiece carrier |

| Workpiece supporting seat, 2pc / set |

| 2 Point Steady Rest |

| 3-jaw scroll chuck |

| BS VM25 Integration system(OD gauging+ crash & gap control + dynamic balance system) |

| BS VM15 Integration system(OD gauging+ crash & gap control) |

| Hydraulic tailstock (w/ foot pedal) |

| Z Axis Heidenhain linear scale (resolution 0.05 um) |

| Manual grinding wheel balance system (vibrator) |

| Grinding wheel dynamic balance system |

| Gap & crash control device |

| Safety door lock |

| Auto gauging device |

| Coolant system with magnetic separator & paper filter |

| Coolant system with magnetic separator |

| Coolant system with paper filter |

| Oil & mist collecting system |

| Spare grinding wheel flange |

| Full-Carbide center tip |

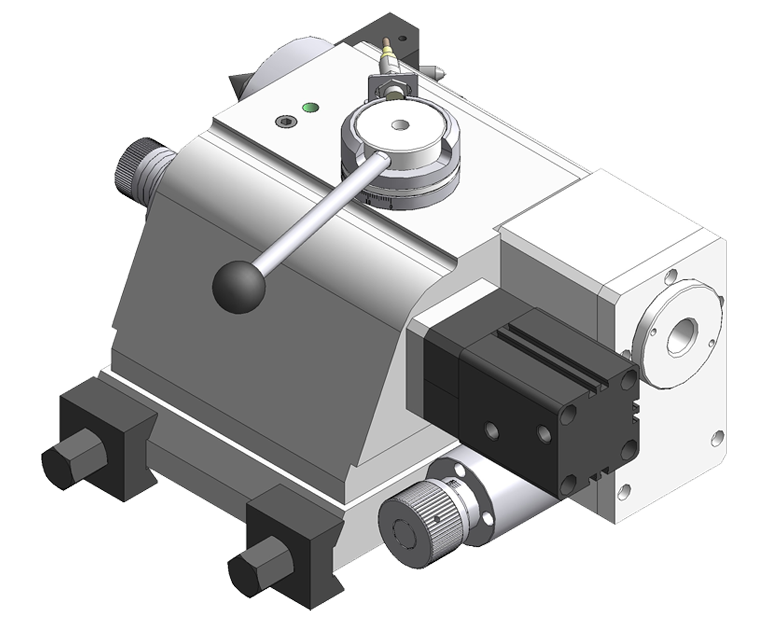

Oil-bath tail stock remains lubrication and makes the machine more durable. Tailstock taper adjustment feature makes workpiece setting faster.

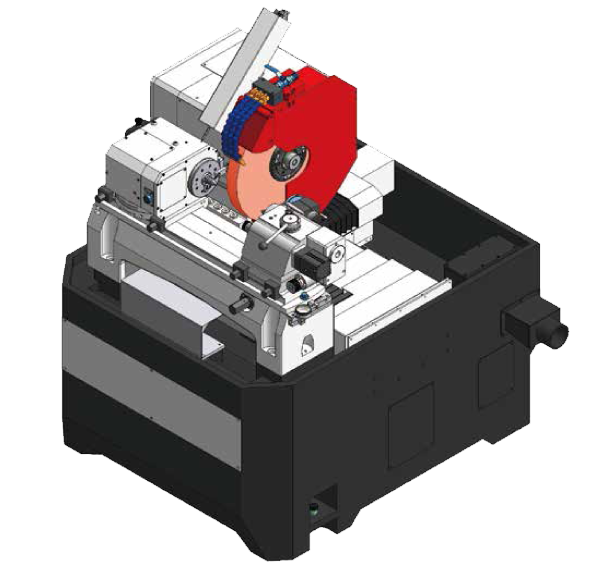

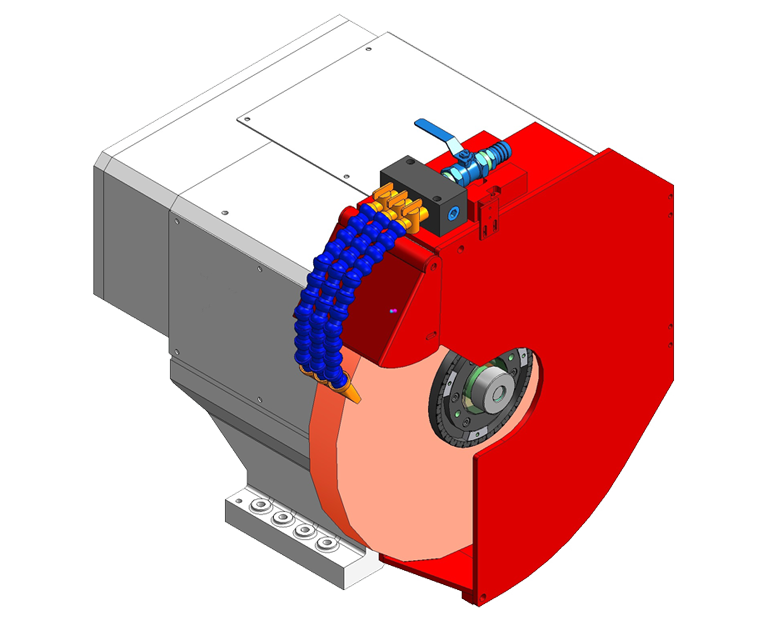

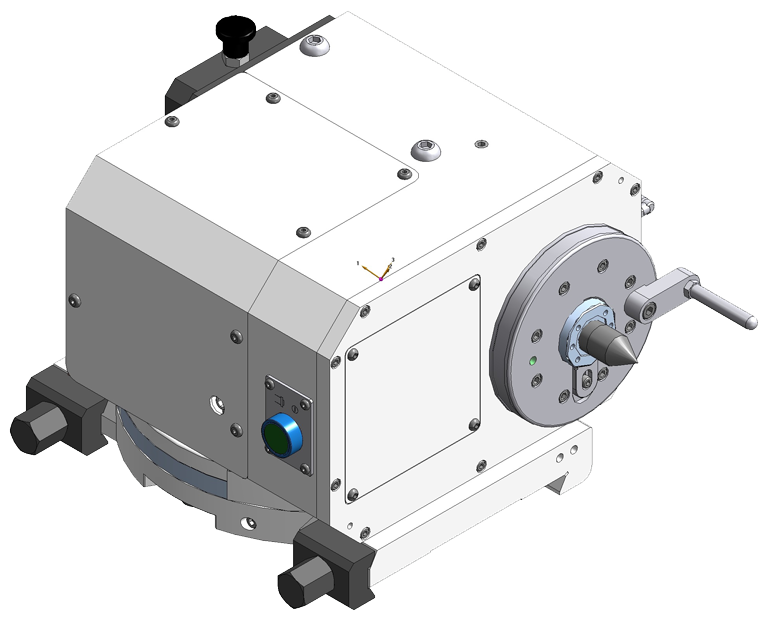

NN bearing designed work spindle with high power motor provides enough power to outer diameter 510mm of wheel head, and improves processing efficiency. The angle of wheel head could be choose as 0 or 20 degree.

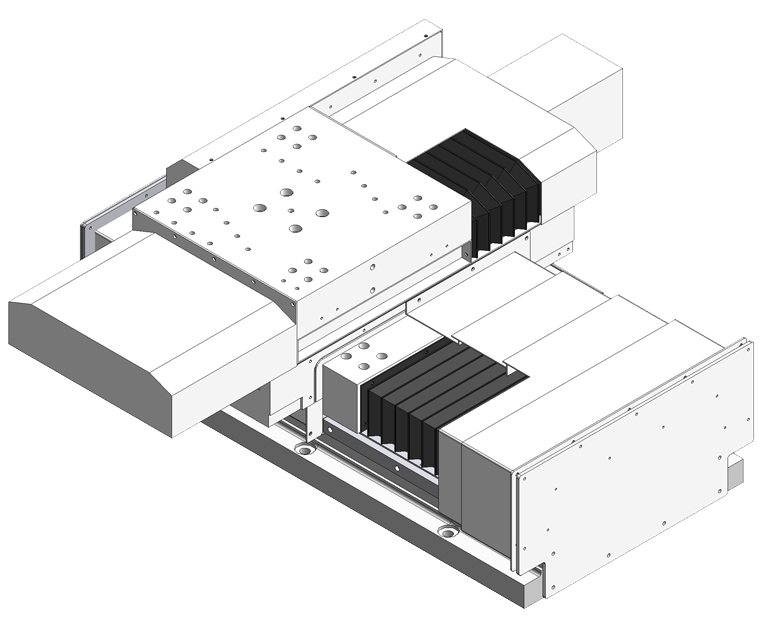

The structure of cross slides is made of Meehanite cast iron. Its good thermostability compensates for temporary temperature changes. (Roller bearing and straight lead rail with Heidenhain linear scale)

NN bearing designed work spindle offers heavy duty load capacity, optimal rotation accuracy, and high rigidity. The servo motor drive offers steady speed and torque during the grinding operation. A positive air purge system keeps grinding swarf and coolant out of the work head, thus it prolongs its life.

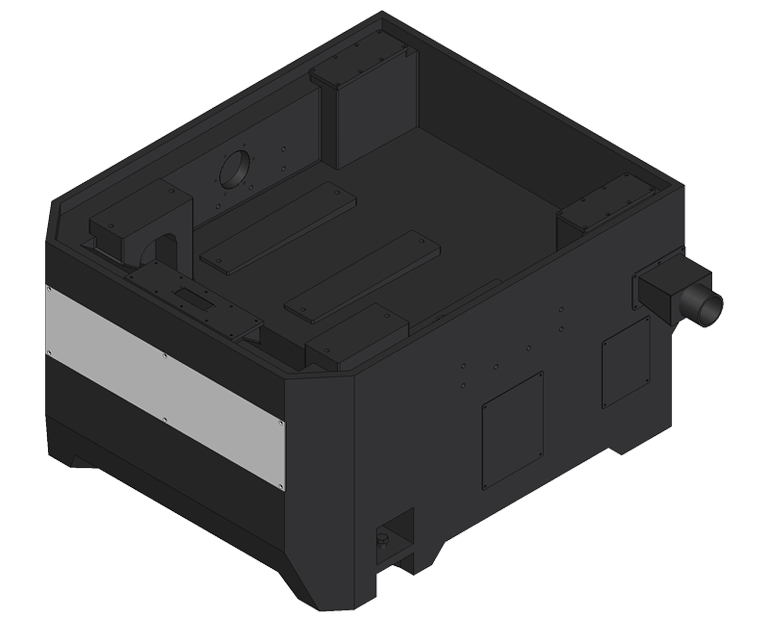

Bath type of machine base is made in Meehanite cast iron, which experience natural aging and twice stress relief to make machine base itself more stable and durable.