Standard grinding cycles and multi-steps graphic

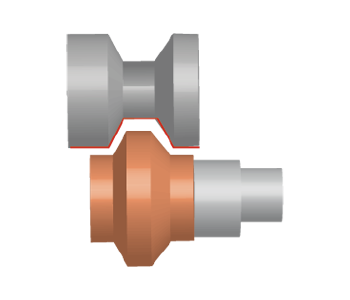

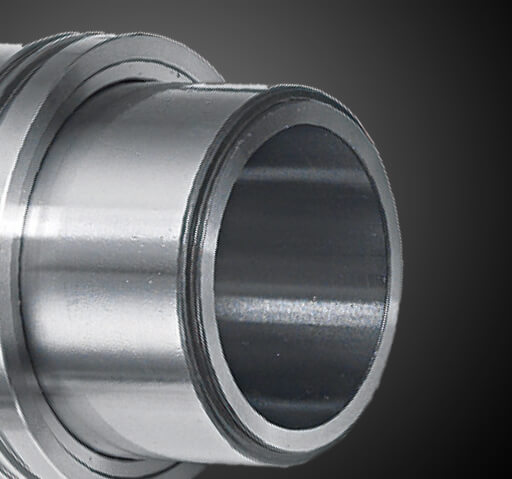

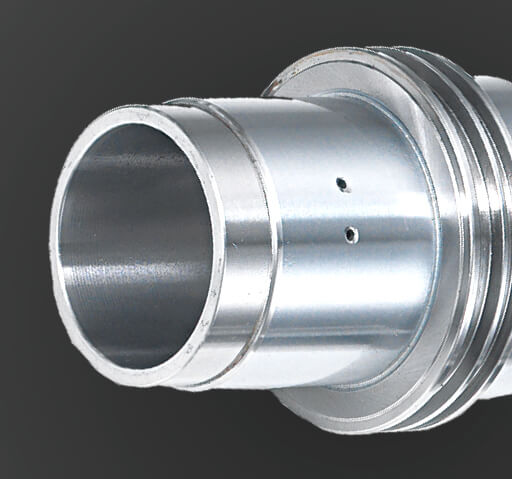

Inner through hole

2 steps straight hole

Inner through hole + outer end-face (gear tip)

Inner blind hole + Inner end-face

Inner taper

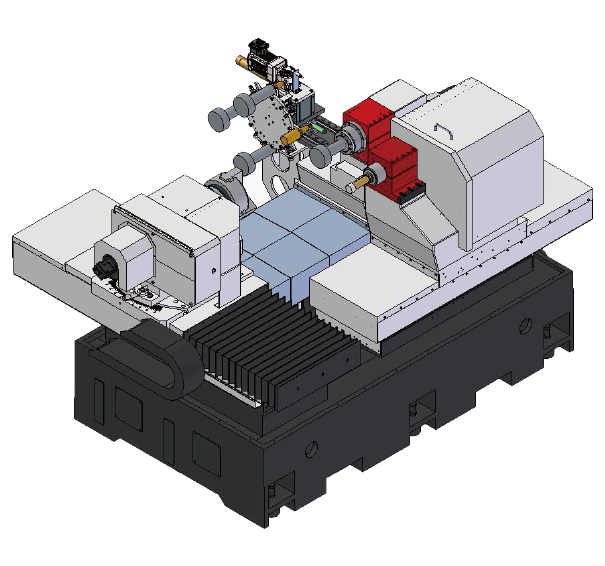

Multi-process in one-stop (EGM-350T)

Inner blind hole + ID chamfer

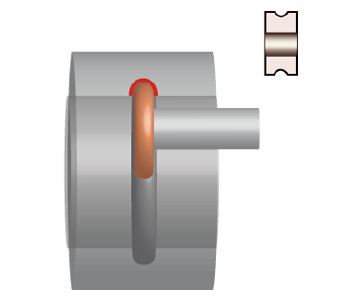

Inner radius grooving

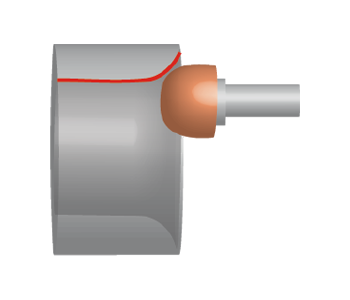

Inner through hole + Inner radius

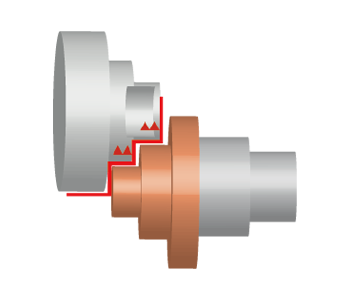

Multi-step grinding

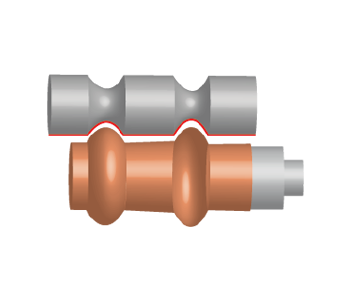

Profile grinding

Inner diameter + End surface

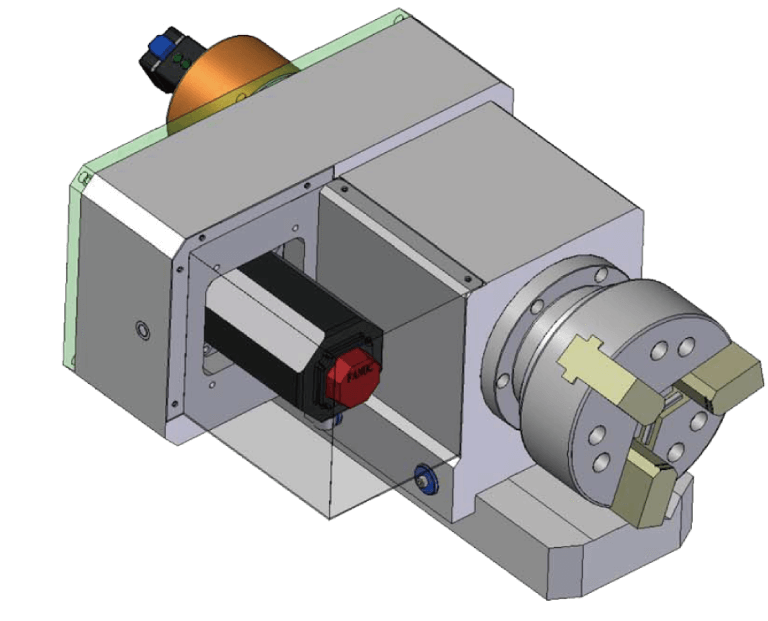

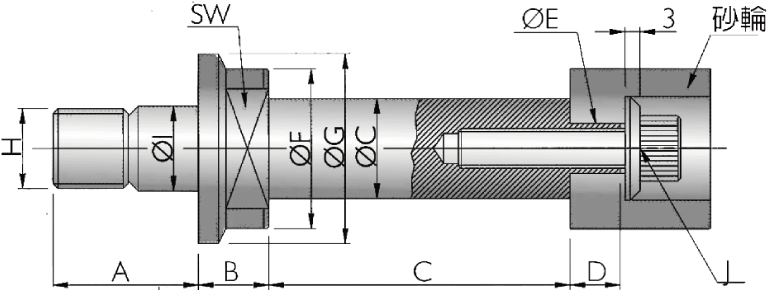

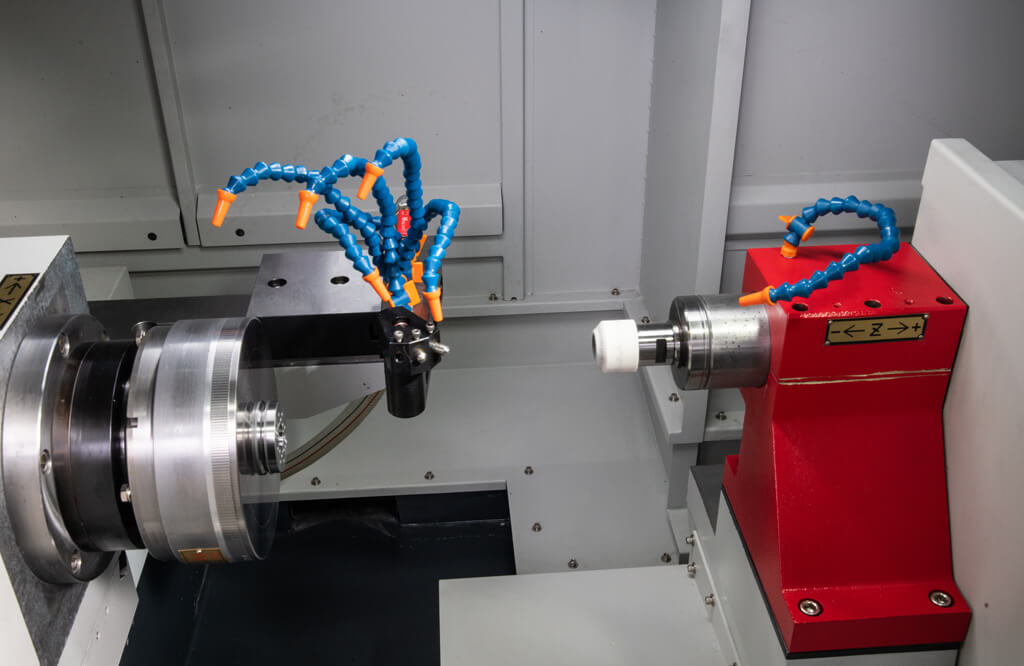

Machine Design Feature

iGrind Operation

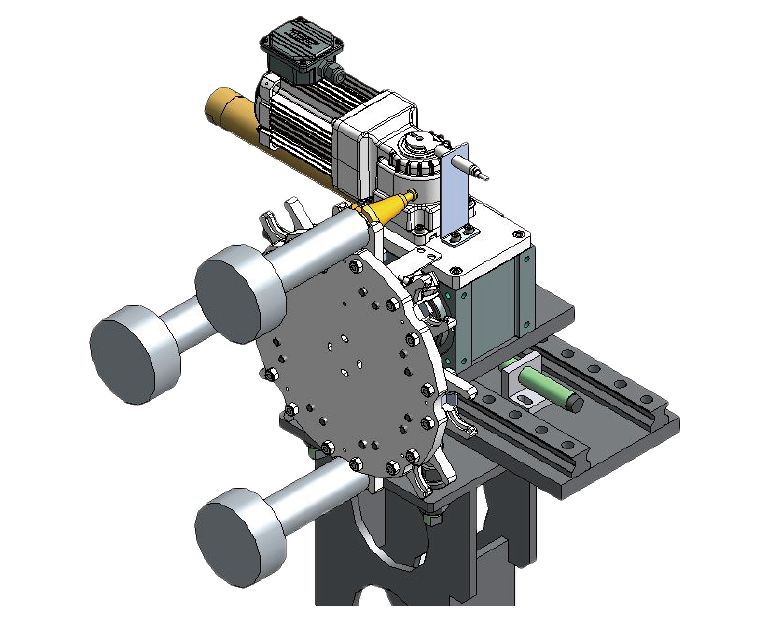

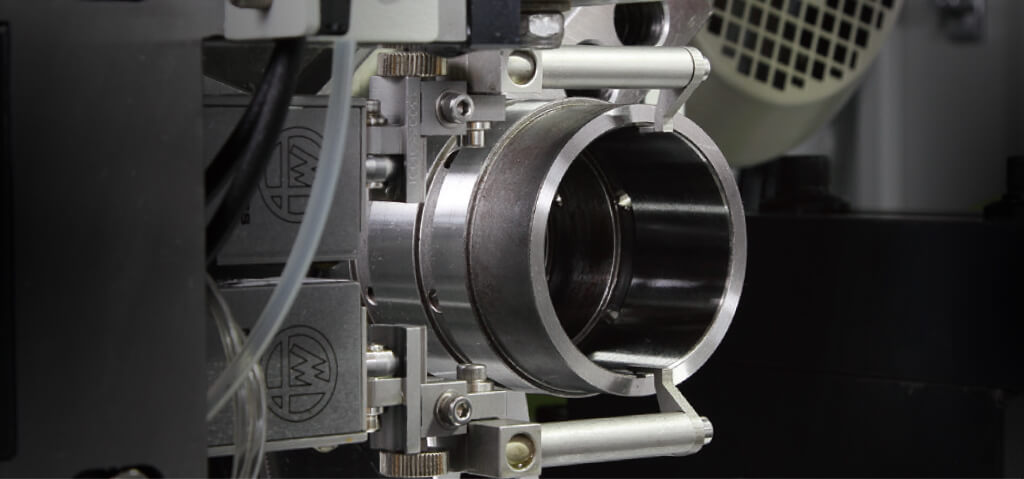

High speed box type dressing.

With EGM high speed box type dressing function, it drastically reduces the wheel dressing time.

This function allows the operator to input the specifications of the dresser and the geometric data of the profile to create the optimal dressing path.

More

Actual Processing

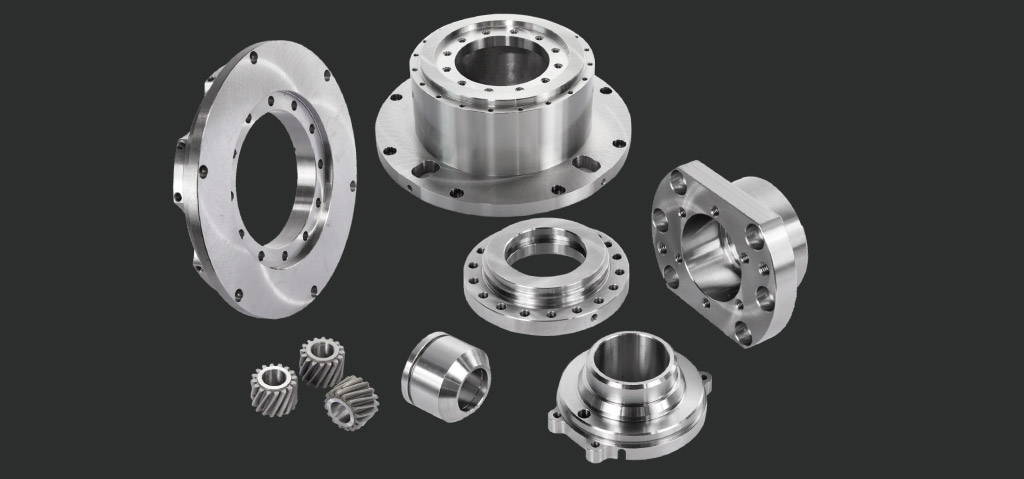

Grinding Sample

| Compare

EGM-350T CNC |

|||

|---|---|---|---|

| General Capacity | Max. grinding ID | mm | φ300 |

| Max. grinding OD | mm | φ400 | |

| Swing over workhead | mm | φ500 | |

| Max. grinding depth | mm | 260 | |

| Max. weight of workpiece | kg | 50 | |

| Max. length of workpie | mm | 300 | |

| Type of workhead | Dual indenpendent wheelhead | ||

| Workhead(X axis) | 3-Jaw chuck | Manual -8"/10"(opt.) | |

| Swiveling angle range | deg | +15°~ -5° | |

| Manual travel distance(toward Z axis) | mm | 250 | |

| Spindle speed | rpm | 0~1000(Variable speed) | |

| Servo motor rated power | kW | Build-in-spindle 1.8(F)/2.2(M) | |

| Wheelhead(Y axis) | OD grinding wheel size | mm | N/A |

| ID grinding wheel size | mm | φ100 | |

| Max. spindle speed | rpm | 30000(std.) | |

| Spindle motor/ max. torque | kW/Nm | 7.5kW / 6Nm | |

| Tool Magazine(Y axis) | Tool holder | BBT30 | |

| Tool Magazine capacity | Qty. | 8 | |

| Max. tool lenght | mm | 100 | |

| Max. tool weight | kg | 3 | |

| Wheelhead(Z axis) | OD grinding wheel size | mm | φ100 |

| ID grinding wheel size | mm | N/A | |

| End face grinding wheel Sub Axis(Opt.Z2) | mm | N/A | |

| Max. spindle speed | rpm | 20,000(std.) | |

| Spindle motor/ max. torque | kW/Nm | 3.75kW / 13Nm | |

| X axis | Travel | mm | 420 |

| Rapid feedrate | mm/min | 8 | |

| Heidenhain linear scale resolution | um | 0.05 | |

| Min. increment | mm | 0.0001 | |

| Servo motor rated power | kW | Build-in-spindle1.8(F)/2.2(M) | |

| Y axis | Travel | mm | 350 |

| Rapid feedrate | mm/min | 8 | |

| Min. increment | mm | 0.0001 | |

| Servo motor rated power | kW | Build-in-spindle 1.8(F)/2.2(M) | |

| Z axis | Travel | mm | 350 |

| Rapid feedrate | m/min | 8 | |

| Min. increment | mm | 0.0001 | |

| Servo motor rated power | kW | Build-in-spindle 1.8(F)/2.2(M) | |

| Motor | Hydraulic motor | kW | 0.75 |

| Lube pump | kW | N/A | |

| Coolant pump | kW | 0.37+0.18 | |

| Machine | Net weight | kg | 5800 |

| Gross weight | kg | 6300 | |

| Packing size (L x W x H) | mm | 3500x2250x1950 |

Standard accessories

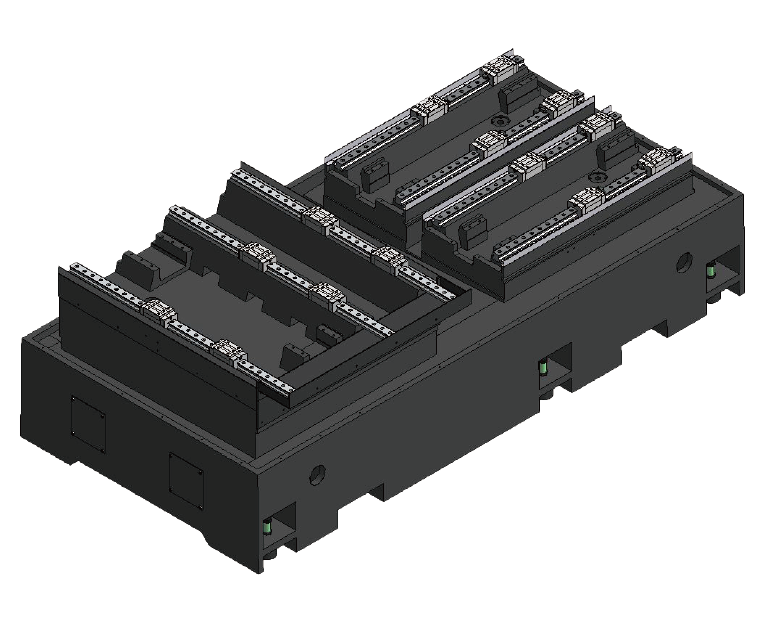

| Control system: Mitsubishi M80 or FANUC 0i-TF with 10.4” screen |

| Three-direction dresser stand x 1 set, diamond dresser x 3 pcs |

| Wheel spindle surface detecting & crash control system (current indicator) |

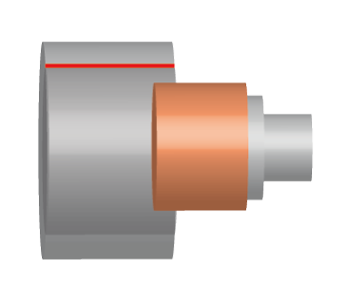

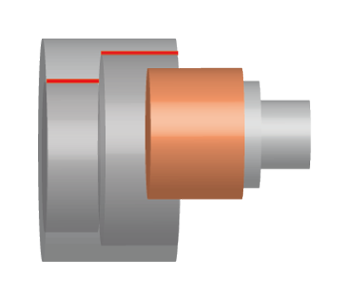

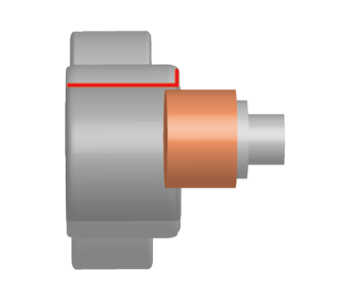

| Grease type grinding wheel spindle: (Select 2 pc from 8,000~50,000RPM) |

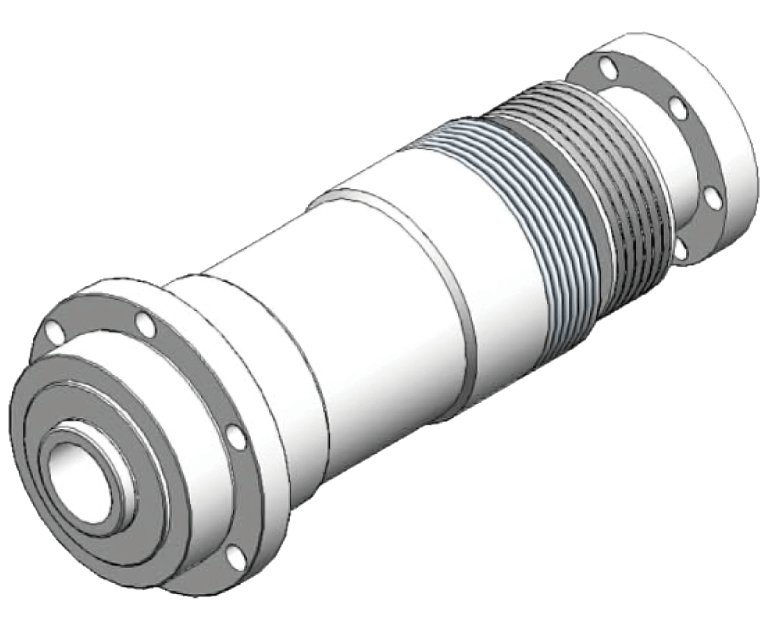

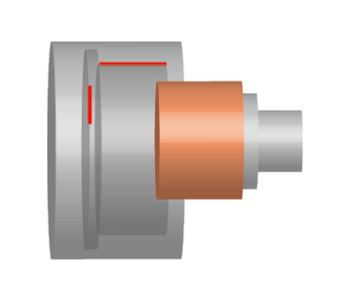

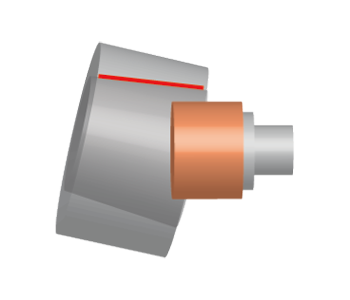

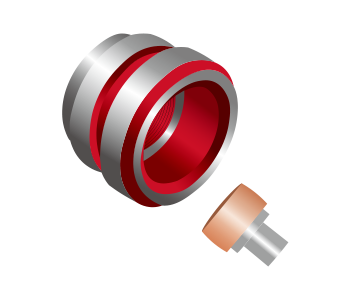

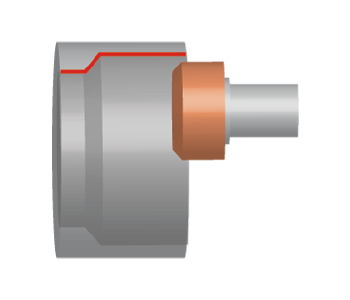

| Hydraulic 8" 3-jaw chuck (w/ solid roary cylinder) |

| MPG handwheel: EGI 2 Axes, EGM 3 Axes control |

| X Axis Heidenhain linear scale (resolution 0.05 um) |

| Electricity cabinet w/ heat exchanger |

| Standard coolant tank 140L |

| Automatic lubrication system |

| 4-color indication signal light |

| Levelling bolts and blocks |

| Tools & tool box |

| Electrical wiring diagram |

| Operation manual & part lists |

| Full-enclosed splash guard |

| Workhead spindle A2-5 |

| Electrical lubricator |

| LED working light |

Optional accessories

| Mitsubishi controller (M80) dressing program: Radius / Taper / Multiple step / form shape |

| Mitsubishi controller (M80) iGrind program |

| Coolant system with magnetic separator & paper filter |

| Coolant system with magnetic separator |

| Coolant system with paper filter |

| CE standard electrical cabinet |

| Electrical cabinet air conditioner |

| Grease type grinding wheel spindle |

| Oil mist type grinding wheel spindle |

| Workhead spindle A2-6 (65mm thru-hole) |

| Manual strong type 7" 3-jaw chuck |

| Oil & mist collecting system |

| Spindle oil mist lubrication system |

| ID auto. gauging device |

| Diamond roller dressing device |

| Dressing sensor system |

| Soft-Jaw turning assembly |

| B axis linear scale w/ digital readout |

| Safety door lock |