Grinding Cycle

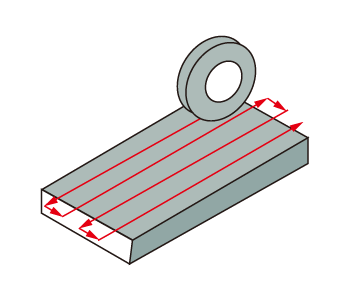

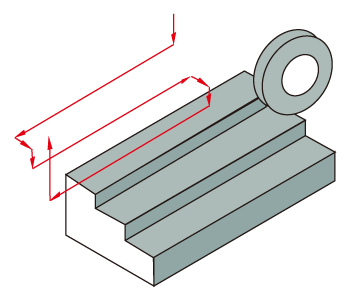

1. Step Grinding

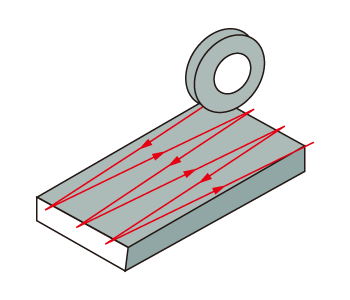

2. Criss-cross Grinding

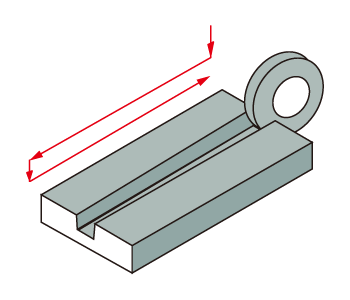

3. Plunge Grinding

4. Multiple Gouges Grinding(opt.)

Machine Design Feature

Specification

| Compare Easy 1224NC |

Compare Easy 1632NC |

Compare Easy 2040NC |

Compare Easy 2060NC |

Compare Easy 2448NC |

Compare Easy 2460NC |

Compare Easy 2480NC |

Compare Easy 24100NC |

Compare Easy 24120NC |

Compare Easy 3248 |

Compare Easy 3280 |

Compare Easy 3260 |

Compare Easy 32100 |

Compare Easy 32120 |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| General Capacity | Table size | mm | 300 x 600 | 400 x 800 | 500 x 1000 | 500 x 1500 | 600 x 1200 | 600 x 1500 | 600 x 2000 | 600 x 2500 | 600 x 3000 | 810x1350 | 810x2150 | 810x1650 | 810x2650 | 810x3150 | |

| Max. grinding length | mm | 600 | 850 | 1050 | 1550 | 1250 | 1550 | 2050 | 2550 | 3050 | 1250 | 2050 | 1550 | 2550 | 3050 | ||

| Max. grinding width | mm | 300 | 400 | 500 | 510 | 610 | 610 | 610 | 610 | 610 | 810 | 810 | 810 | 810 | 810 | ||

| Distance from table surface to spindle centerline | mm | 550 | 550 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 800 (Std.) / 1000 (Opt.) | 800 (Std.) / 1000 (Opt.) | 800 (Std.) / 1000 (Opt.) | 800 (Std.) / 1000 (Opt.) | 800 (Std.) / 1000 (Opt.) | ||

| Standard magnetic chuck size | mm | 300 x 600 | 400 x 800 | 500 x 1000 | 500 x 1500 | 600 x 1200 | 600 x 1500 | 600 x 2000 | 600 x 2500 | 600 x 3000 | 800 x 1200 | 800 x 2000 | 800 x 1500 | 800 x2500 | 800 x 3000 | ||

| Saddle/Column moving | mm | Saddle moving | Saddle moving | Column moving | Column moving | Column moving | column moving | Column moving | Column moving | Column moving | Column moving | Column moving | Column moving | Column moving | Column moving | ||

| Grinding Wheel | Diameter x Width x Bore | mm | Ø355x50xØ127 | Ø355x50xØ127 | Ø405x50xØ127 | Ø405x50xØ127 | Ø405x50xØ127 | Ø405x50xØ127 | Ø405x50xØ127 | Ø405x50xØ127 | Ø405x50xØ127 | Ø510 x 50 x Ø127 (Std.) Ø510 x 75 xØ127 (Opt.) |

Ø510 x 50 x Ø127 (Std.) Ø510 x 75 xØ127 (Opt.) |

Ø510 x 50 x Ø127 (Std.) Ø510 x 75 xØ127 (Opt.) |

Ø510 x 50 x Ø127 (Std.) Ø510 x 75 xØ127 (Opt.) |

Ø510 x 50 x Ø127 (Std.) Ø510 x 75 xØ127 (Opt.) |

|

| Spindle speed (60HZ) | rpm | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1100 | 1100 | 1100 | 1100 | 1100 | ||

| X axis | Table speed (Infinite variable) | mm | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | 3 - 25 | |

| Y axis | Rapid travel | mm/min | 190 | 190 | 285 | 285 | 280 | 280 | 280 | 280 | 280 | 280 | 280 | 280 | 280 | 280 | |

| Automatic downfeed | mm | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.03 | 0.001 - 0.05 | 0.001 - 0.05 | 0.001 - 0.05 | 0.001 - 0.05 | 0.001 - 0.05 | ||

| Handwheel per graduation | mm | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.01/0.1/1(MPG) | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | ||

| Handwheel per revolution | mm | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10 (MPG) | 0.1/1/10(MPG) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||

| Z axis | Manual travel | mm | 370 | 470 | 560 | 560 | 660 | 660 | 660 | 660 | 660 | 860 | 860 | 860 | 860 | 860 | |

| Rapid travel, approx. | mm/min | 0.5 - 1 | 0.5 - 1 | 0.5 - 1 | 0.5 - 1 | 0.5 - 1 | 0.5 - 1 | 0.5 - 1 | 0.5 - 1 | 0.5 - 1 | 0.5 - 1.5 | 0.5 - 1.5 | 0.5 - 1.5 | 0.5 - 1.5 | 0.5 - 1.5 | ||

| Automatic increment feeds | mm/min | 0.5 - 8 | 0.5 - 8 | 2 - 10 | 2 - 10 | 2 - 10 | 2 - 10 | 2 - 10 | 2 - 10 | 2 - 10 | 1 - 15 | 1 - 15 | 1 - 15 | 1 - 15 | 1 - 15 | ||

| Handwheel per graduation | mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.001/0.01/0.1(MPG) | 0.001/0.01/0.1(MPG) | 0.001/0.01/0.1(MPG) | 0.001/0.01/0.1(MPG) | 0.001/0.01/0.1(MPG) | 0.02 (Opt.) | 0.02 (Opt.) | 0.02 (Opt.) | 0.02 (Opt.) | 0.02 (Opt.) | ||

| Handwheel per revolution | mm | 5 | 5 | 5 | 5 | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 0.1/1/10(MPG) | 5 | 5 | 5 | 5 | 5 | ||

| Motor | Spindle motor | HP | 5 | 5 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 15 (Std.) 18 (Opt.) (6 Poles) |

15 (Std.) 18 (Opt.) (6 Poles) |

15 (Std.) 18 (Opt.) (6 Poles) |

15 (Std.) 18 (Opt.) (6 Poles) |

15 (Std.) 18 (Opt.) (6 Poles) |

|

| Crossfeed Z axis motor | 0.2 | 0.2 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 | 500W | 500W | 500W | 500W | 500W | |||

| Elevating Y axis motor | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 1 | 1 | 1 | 1 | 1 | |||

| Hydraulic motor | Kw | 2 | 2 | 3 | 5 | 5 | 5 | 5 | 5 | 5 | 7.5 | 10 | 5 | 10 | 10 | ||

| Machine | Net weight | kg | 3000 | 3900 | 4700 | 6560 | 6100 | 8800 | 9850 | 10900 | 11990 | 7900 | 10100 | 8700 | 11500 | 12700 | |

| Gross weight | kg | 3200 | 4200 | 5100 | 7500 | 6600 | 9800 | 10650 | 11700 | 12800 | 7400 | 9500 | 8200 | 11000 | 12000 | ||

| Packing size (L x W x H) | mm | 2850x2250x2490 | 3060x2260x2550 | 3500x2280x2550 | 4860x2250x2250 | 3060x2240x2070 | 5180 x2280 x2550 | 6290 x 2280 x 2550 | 7600 x 2280 x 2550 | 7700 x 2650 x 2550 | 40HQ | 40HQ | 40HQ | 40HQ | 40HQ | ||

Standard accessories

| standard grinding wheel with flange |

| Working light |

| Leveling screws with blocks |

| Balancing stand with arbor |

| Wheel extractor |

| Operation manual with part list |

| Tools and tool box |

| Diamond kit with holder |

| Splash guard |

| Standard coolant tank |

Optional accessories

| Coolant system with magnetic separator and paper filter |

| Coolant system with magnetic separator |

| Chiller |

| Rotary table |

| Roller type dressing attachment |

| Diamond wheel dressing attachment |

| Demagnetizer (Standard) |

| Demagnetizer (Hi-power) |

| Electromagnetic chuck (fine pole) |

| Angle dressing attachment |

| Radius dressing attachment |

| Parallel dressing attachment (manual) |

| Scope type dressing attachment |

| Dual sides dressing attachment |

| Roller type balancing stand |

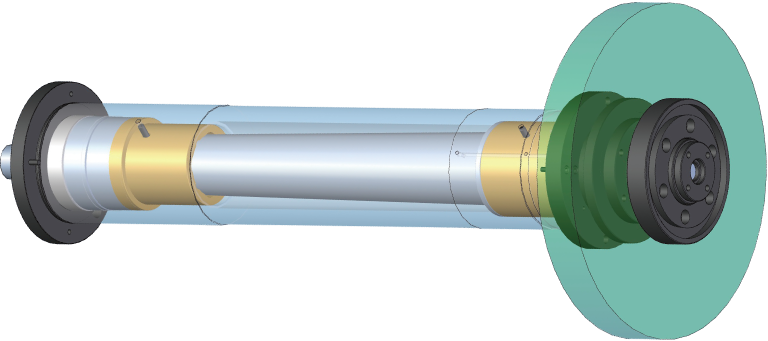

Wheel spindle air blowing design

Wheel spindle air blowing design could create positive pressure. It effectively prevents dust going into the spindle, and maintains the internal coolant of the spindle. The catrige spindle itself has a outer spiral groove design, and it could effectively prevents the spindle from thernal raising.

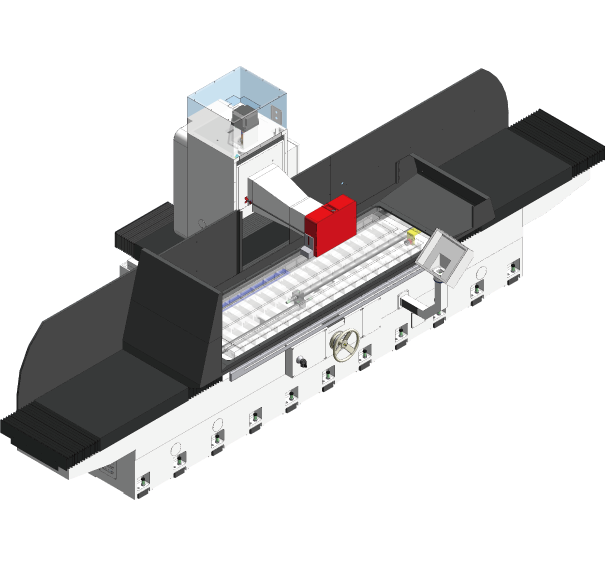

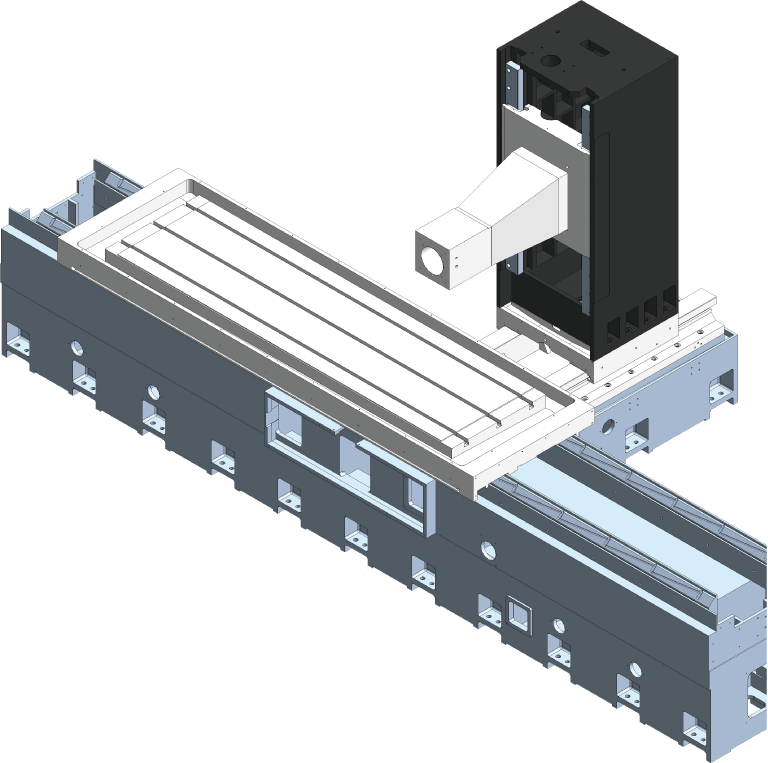

Rigid rib-box structure

Rigid rib-box structure is consist with the same material level of Meehamite base casting, ensuring the machine rigidity and stability. Machine net weight: 2,200kg.

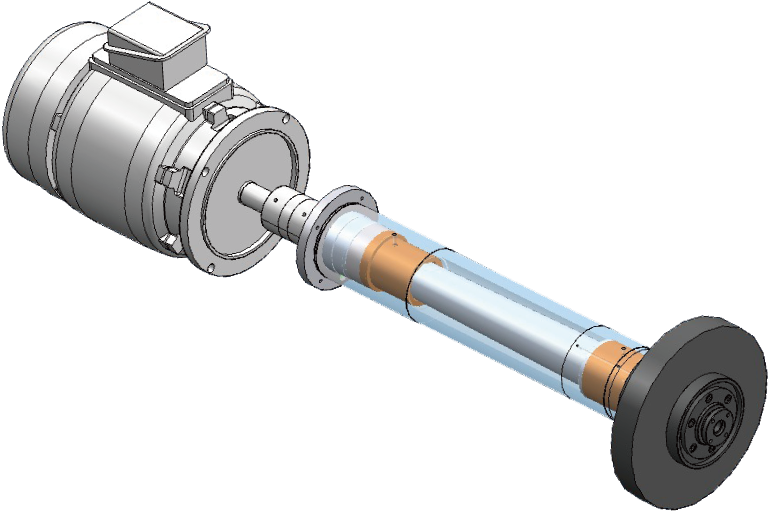

15HP spindle motor

Heavy duty spindle with 15HP spindle motor allows the machine to grind hard material or to grind with creep feeding operationMachine design

435mm(17.12“)wide column design: Comparing with other manufacturer, it provides better stability and rigidity.

Machine design

774mm wide machine base design provides excellent machine rigidity, and low dynamic grinding operation

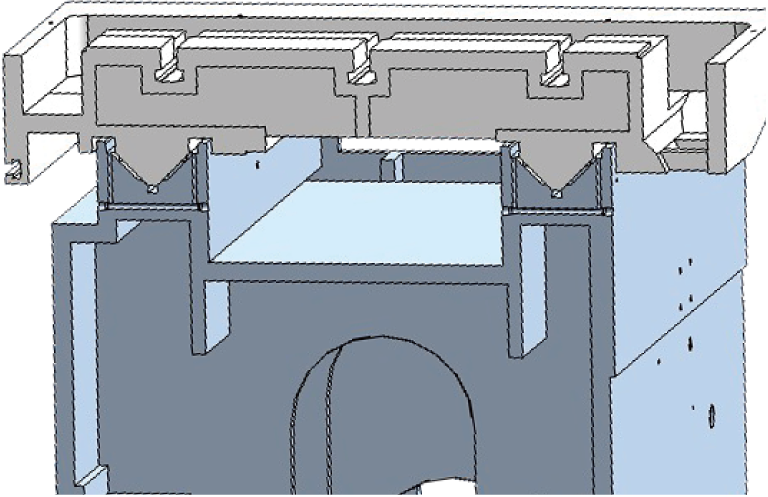

X Axis Working table guideway double V design

X Asis guideway is precisely hand scraped, oil firm lubrication supplied, and Turcite-B coated to ensure positioning accuracy and long term usage.

Column Type Integral "T" Shape Base

- The integral "T" shape base is manufactured from Meehanite casting, with tempering & stress-relief treatment to ensure structure stability. The base is 2.5 times longer than the worktable. This design allows the work table to not only be fully be fully supporting during the whole travel, but also increases the rigidity when grinding.

- The worktable slideways are modified as double V guideways. Deepened and widened guideway with large span design enables the worktable to move steadily and smoothly for large workpieces grinding. Special lubrication circuit design ensures the worktable to be fully supported by oil film pressure and decrease the frictions to prolong the use time of the machines.

- The guideway lubrication system comes with a pressure switch sensor to make sure the machine has enough oil film pressure.

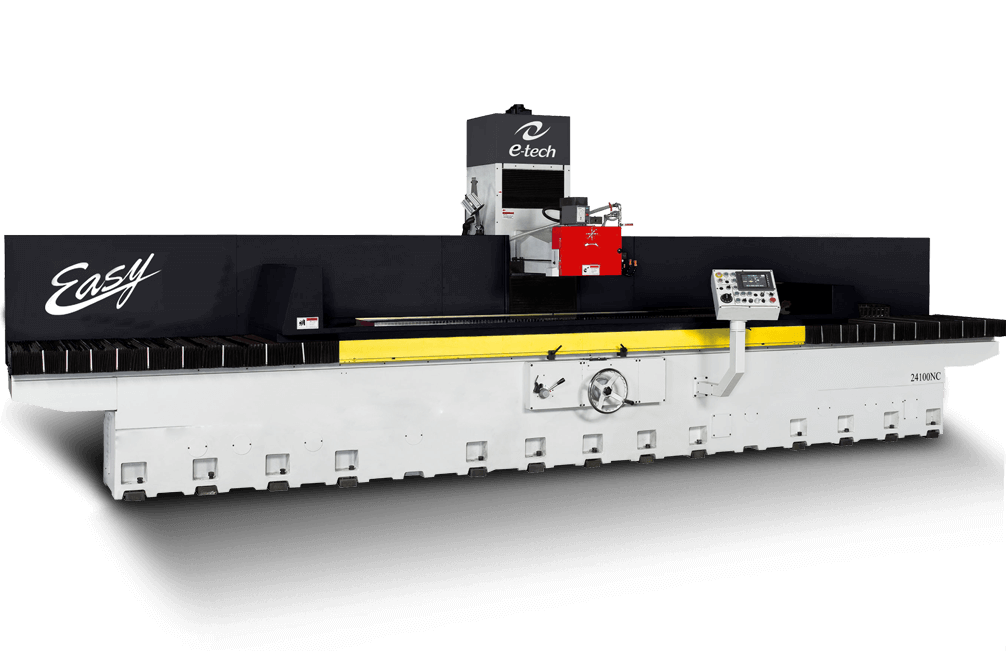

Specifically Built for Mold and High-tech Electronic Industries

E-tech Easy Series Surface Grinders present unique grinding accuracy and surface finish. The column type structure design. Easy series are all embedded a PLC control panel and a touch screen for easy operation; furthermore, the auto-grinding function meets the target of time saving and high efficiency.

E-tech Easy Series Surface Grinders present unique grinding accuracy and surface finish. The column type structure design. Easy series are all embedded a PLC control panel and a touch screen for easy operation; furthermore, the auto-grinding function meets the target of time saving and high efficiency.

Specifically Built for Mold and High-tech Electronic Industries

E-tech Easy Series Surface Grinders present unique grinding accuracy and surface finish. The column type structure design. Easy series are all embedded a PLC control panel and a touch screen for easy operation; furthermore, the auto-grinding function meets the target of time saving and high efficiency.

E-tech Easy Series Surface Grinders present unique grinding accuracy and surface finish. The column type structure design. Easy series are all embedded a PLC control panel and a touch screen for easy operation; furthermore, the auto-grinding function meets the target of time saving and high efficiency.

Saddle Type Structure

- The base uses strong box structure. The highly rigid base provides steady support that ensures the long-term precision.

- The double V design of the base slideways improves the supporting stability.

- The interior strengthened rid design effectively increases the structure rigidity.