Graphic conversational dressing modes

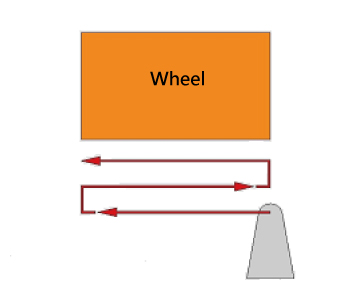

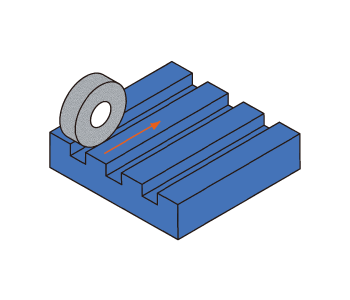

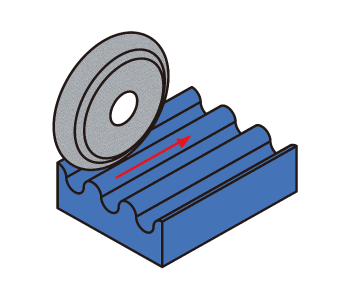

Flat Dress

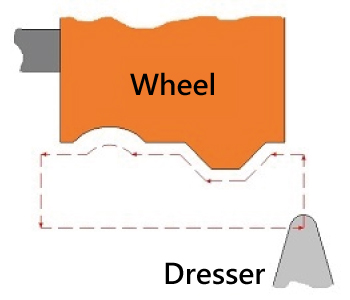

Profile Dress

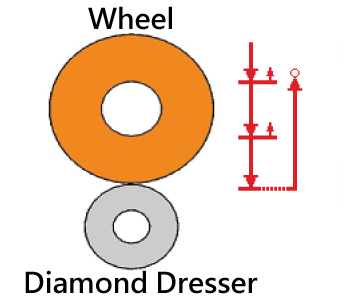

Forming

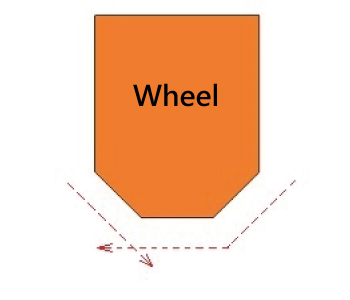

Chamfer

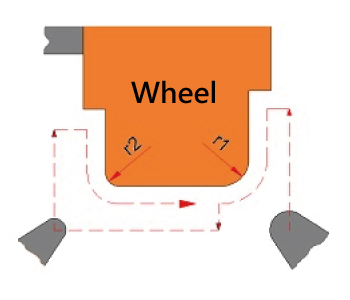

Two Side Radius

Graphic conversational grinding modes

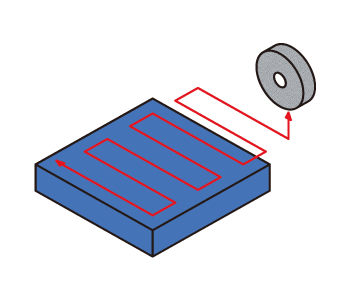

Surface Grinding

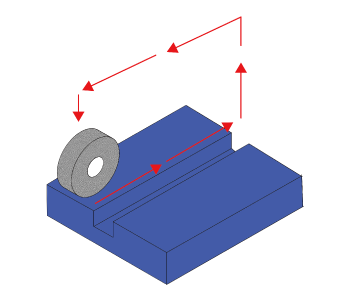

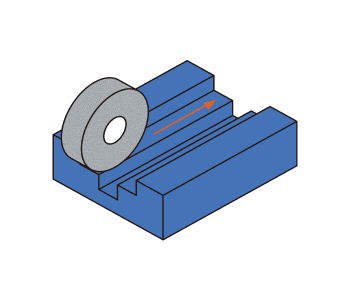

Slice Grinding(Single Way)

Vari-Pitch/Depth

Step Grinding

Profile Grinding

Machine Design Feature

Control Features

- Multiple Box Slicing function

- High speed wheel dressing

- 0.001 mm (0.0001”) least increment input.

- Graphic conversational programing for Grinding and Dressing with automatic compensation

- Grinding path simulation mode by turning MPG

- Graphic grinding path display

- Surface / Slice / Crisscross / Profile grinding modes are standard

- Additional final finish grinding function after cycle end

- Part program can be stored for future grinding purpose

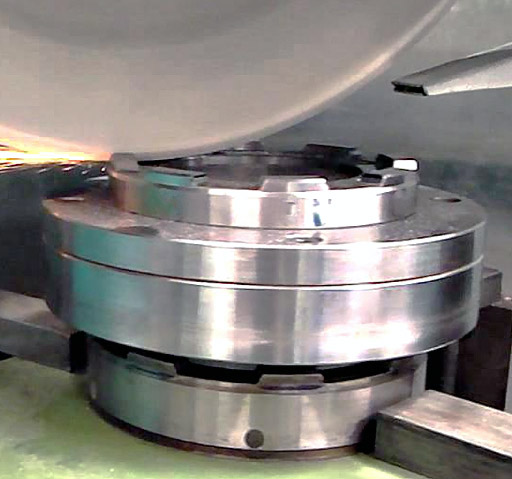

Grinding Sample

Specification

| Compare 820CNC II |

Compare 820CNC III |

Compare 1224CNC II |

Compare 1224CNC III |

Compare 1632CNC II |

Compare 1632CNC III |

Compare 2040CNC II |

Compare 2040CNC III |

Compare 2060CNC II |

Compare 2060CNC III |

Compare 2448CNC II |

Compare 2448CNC III |

Compare 2460CNC II |

Compare 2460CNC III |

Compare 2480CNC II |

Compare 2480CNC III |

Compare 24100CNC II |

Compare 24100CNC III |

Compare 24120CNC II |

Compare 24120CNC III |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | Maximum grinding (width x length) | mm | 200X500 | 200X500 | 300X600 | 300X600 | 400X800 | 400X800 | 500X1000 | 500X1000 | 500X1800 | 500X1800 | 600X1200 | 600X1200 | 600X1500 | 600X1500 | 600X2000 | 600X2000 | 600X2500 | 600X2500 | 600X3000 | 600X3000 | |

| Maximum distance for table surface to spindle centerline | mm | 500 | 500 | 560 | 560 | 560 | 560 | 600 | 600 | 600 | 600 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| Table | Table size (width x length) | mm | 200X500 | 200X500 | 300X600 | 300X600 | 400X800 | 400X800 | 500X1000 | 500X1000 | 500X1500 | 500X1500 | 600X1200 | 600X1200 | 600X1500 | 600X1500 | 600X2000 | 600X2000 | 600X2500 | 600X2500 | 600X3000 | 600X3000 | |

| Maximum longitudinal travel | mm | 600 | 600 | 710 | 710 | 900 | 900 | 1060 | 1060 | 1060 | 1060 | 1260 | 1260 | 1560 | 1560 | 2060 | 2060 | 2560 | 2560 | 3060 | 3060 | ||

| Maximum cross travel | mm | 240 | 240 | 320 | 320 | 415 | 415 | 560 | 560 | 560 | 560 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | 660 | ||

| T-slot (No. x width) | mm | 1X13 | 1X13 | 1X13 | 1X13 | 1X13 | 1X13 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | 3X14 | ||

| Longitudinal Movement | Hydraulic transverse feed | m/min | 25 | - | 25 | - | 25 | - | 25 | - | 25 | - | 25 | - | 25 | - | 25 | - | 25 | - | 25 | - | |

| Rapid transverse servo feed | m/min | - | 20 | - | 20 | - | 20 | - | 20 | - | 20 | - | 20 | - | 20 | - | 20 | - | 20 | - | 20 | ||

| Cross Movement | Rapid transverse feed | m/min | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Least increment input | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | ||

| Elevation Movement | Rapid feed | m/min | 5 | 5 | 5 | 5 | 5 | 5 | 3 | 3 | 3 | 3 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Least increment input | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | ||

| Spindle & Wheel | Spindle motor | HP | 3HP (5HP opt.) | 3HP (5HP opt.) | 5HP | 5HP | 10HP | 10HP | 10HP (15HP opt.) | 10HP (15HP opt.) | 10HP (15HP opt.) | 10HP (15HP opt.) | 15HP | 15HP | 15 HP | 15 HP | 15 HP | 15 HP | 15 HP | 15 HP | 15 HP | 15 HP | |

| Spindle speed | rpm | 3600 | 3600 | 1800 | 1800 | 1800 | 1800 | 1800 (1100rpm opt.) | 1800 (1100rpm opt.) | 1800 | 1800 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | ||

| Grinding wheel outside diameter | mm | ø200X13 | ø200X13 | ø360X50 | ø360X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ø410X50 | ||

| Grinding wheel bore | mm | ø30 | ø30 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ø127 | ||

| Motor | Hydraulic motor | Kw | 0.74 | - | 1.4 | - | 1.4 | - | 3 | N/A | 5 | N/A | 5 | N/A | 5 | N/A | 5 | N/A | 5 | N/A | 5 | N/A | |

| Cross feed (AC servo) | kw | 1 | 1 | 1 | 1 | 1 | 1 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | ||

| Vertical feed (AC servo) | kw | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Longitudinal feed (AC servo) | kw | - | 1 | - | 1 | - | 1 | - | 2 | - | 2 | - | 3 | - | 3 | - | 3 | - | 3 | - | 3 | ||

| Machine | Net weight | kg | 2200 | 2200 | 4050 | 4050 | 4500 | 4500 | 4900 | 4900 | 6560 | 6560 | 6100 | 6100 | 8800 | 8800 | 9850 | 9850 | 10900 | 10900 | 11990 | 11990 | |

| Gross weight | kg | 2400 | 2400 | 4500 | 4500 | 5100 | 5100 | 5500 | 5500 | 7500 | 7500 | 6600 | 6600 | 9800 | 9800 | 10650 | 10650 | 11700 | 11700 | 12800 | 12800 | ||

| Packing size (L x W x H) | mm | 2290X2035X2290 | 2290X2035X2290 | 2850X2250X2590 | 2850X2250X2590 | 3073X2316X2590 | 3073X2316X2590 | 3500X2280X2550 | 3500X2280X2550 | 4860X2250X2250 | 4860X2250X2250 | 3060X2240X2070 | 3060X2240X2070 | 5180X2280X2550 | 5180X2280X2550 | 6290X2280X2550 | 6290X2280X2550 | 7600X2280X2550 | 7600X2280X2550 | 8200X2650X2550 | 8200X2650X2550 | ||

Standard accessories

| Leveling Bolts with Blocks |

| Balancing Stand |

| Tool Box with Tools |

| Grinding Wheel with Flange |

| Wheel Extractor |

| Spindle Inverter |

| Diamond Pen with Holder |

| Working Light |

| Three-Color Warning Lights |

| Operation Manual and Part List |

| Coolant Tank |

| Splash Guard For Table |

Optional accessories

| Electromagnetic Chuck. |

| Permanent Magnetic Chuck |

| Fine-Pole Permanent Magnetic Chuck |

| Tilting Permanent Magnetic Chuck |

| Chuck Controller |

| Oil Mist Collector |

| Dust And Mist Collector |

| Dust Collector |

| Rotary Table |

| Indexing Table |

| Single Disc Roller Dresser |

| Multi-tip Diamond Dresser |

| Roller Type Balancing Stand |

| Linear Scale (Y/Z Axis) |

| Fully Enclosed Splash Guard |

| Extra Grinding Wheel Flange |

| Coolant System w/ Magnetic Separator |

| Coolant System w/ Paper Filter |

| Coolant System w/ Magnetic Separator and Paper Filter |

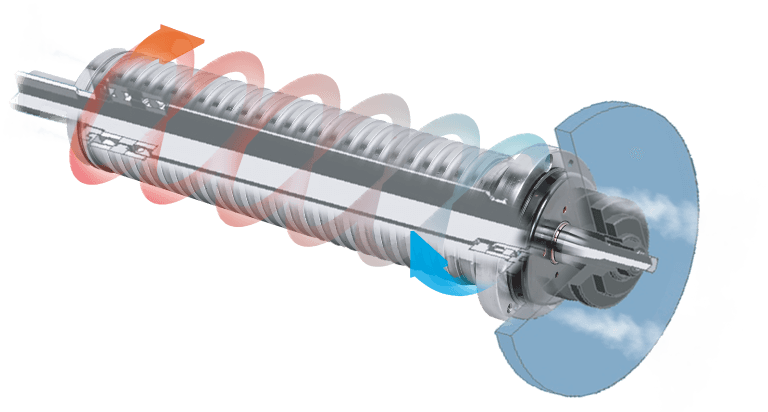

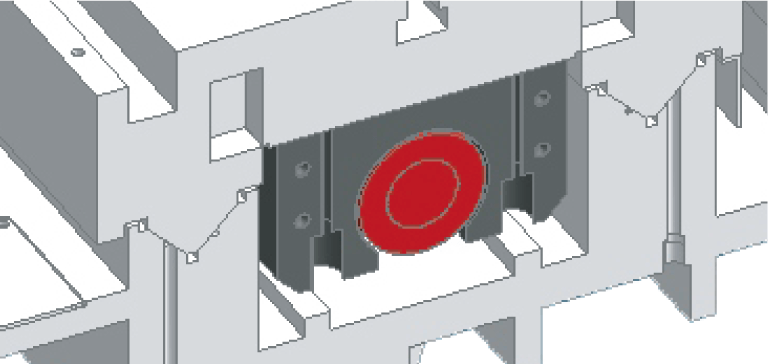

Spindle Air Purge design

The air purge designed spindle generates positive air pressure between the spindle and spindle housing. The spiral groove design helps keep the spindle cool and efficiently prevents small chips from entering.

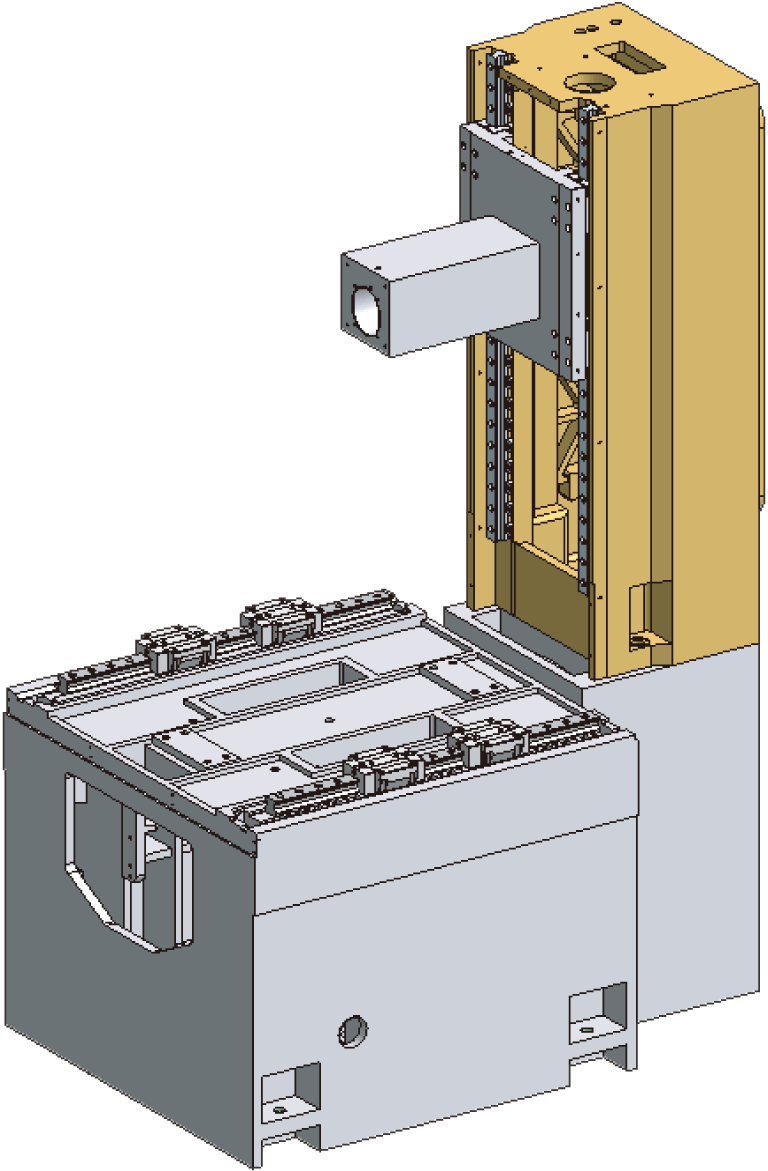

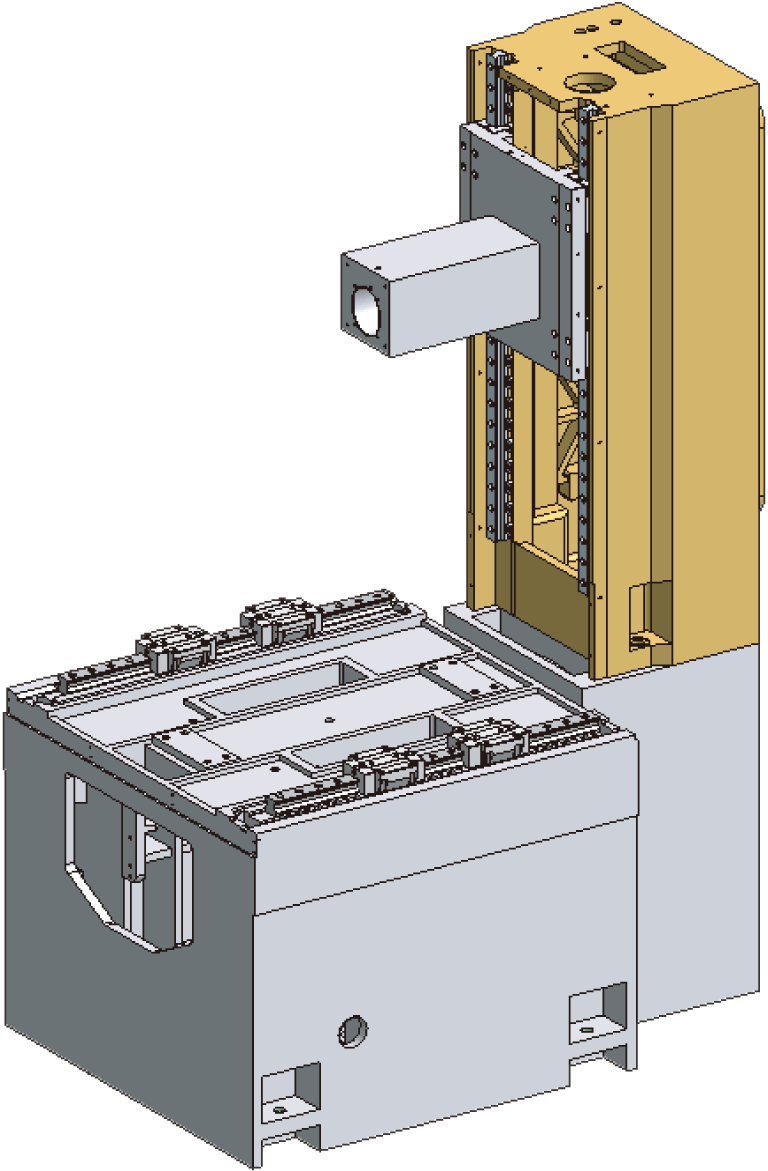

Machine Design

Extra wide 774mm (30.47”) machine base design, providing excellent rigidity for low vibration dynamic grinding, 435mm (17.12”) large column

5 HP Spindle Motor (EASY 820)

An optional 5 HP spindle motor is available to work with the ultra heavy duty spindle for tough material or creepfeed grinding.

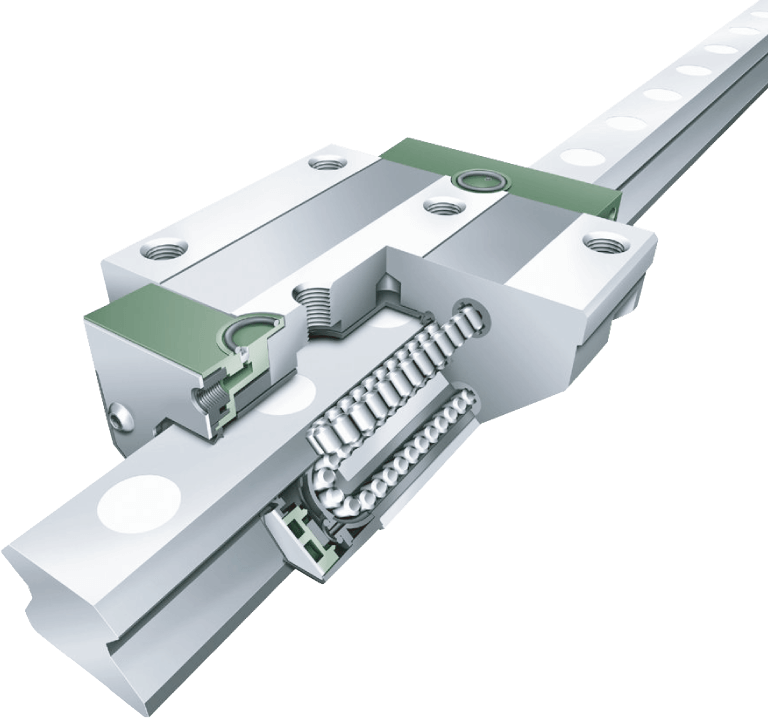

Roller Type Linear Ways

Roller type linear guide ways are used in Y axis and Z axis of EASY-820 for superb rigidity and micro feed acuracy.

Precision hand scraped longitudinal travel guideways with hydrostatic oil film technology and Turcite-B coating to assure the positioning accuracy and machine longevity.

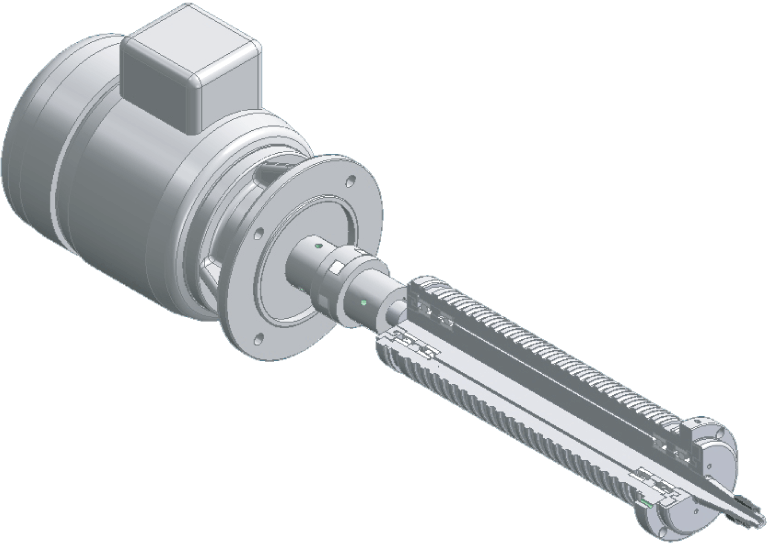

X, Y, and Z axes are driven by A.C. servo motor and precision ballscrews, providing high positioning accuracy and repeatability.

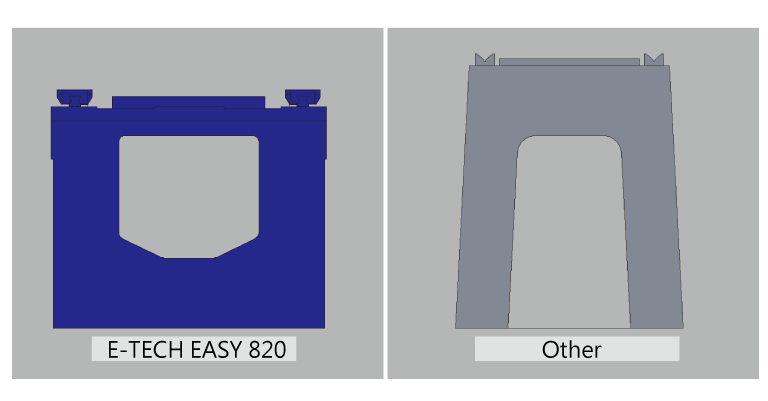

Ultra Rigid Box Structure Design

Box-structure machine base is made of Meehanite cast-iron to guarantee the superior rigidity and stability of machine. Machine net weight : 2,200 kgs (4,840 lbs).

EASY series machines can be configured as 2 or 3 axes CNC.

Table size ranges are 200x500, 300x600 and 400x800 mm.

to max. 600x3000mm.

The EASY series CNC surface and profile grinder with its EASY to learn,

EASY to program, shop floor language, is indeed an innovation for

close-tolerance, repeatable, multi-purpose grinding. The EASY Series

incorporates all the excellent features required for high precision

grinding. Due to the machines versatility, it is suitable for numerous

high accuracy, complex contouring and forming applications.

The operator doesn’t need to use G or M codes to program the

grinding functions. You just input the grinding values into the graphic

conversational screen for both grinding and wheel dressing cycles.

The EASY control also allows for G or M code programing or down

loading programs from a CAD file through the USB ports.