Application Samples

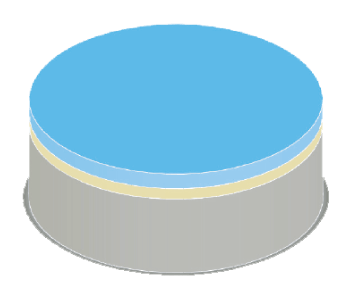

Surface Grinding

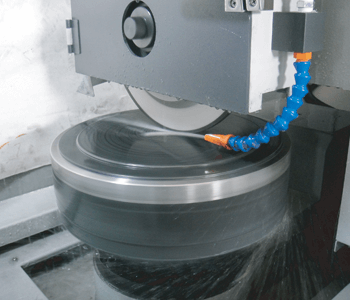

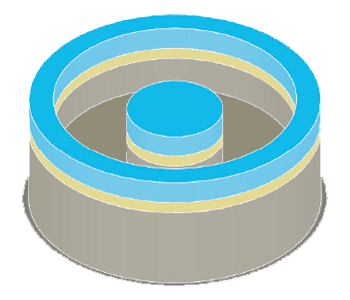

Plunge Grinding

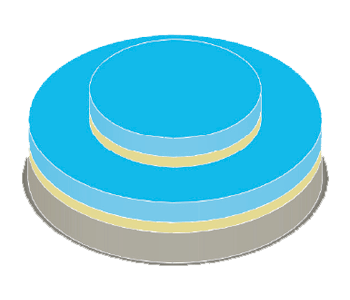

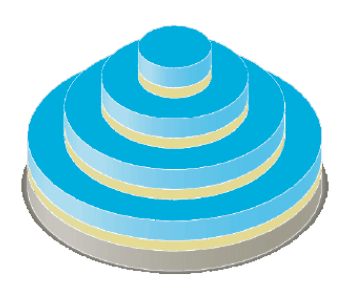

Step Grinding

Multiple Grinding

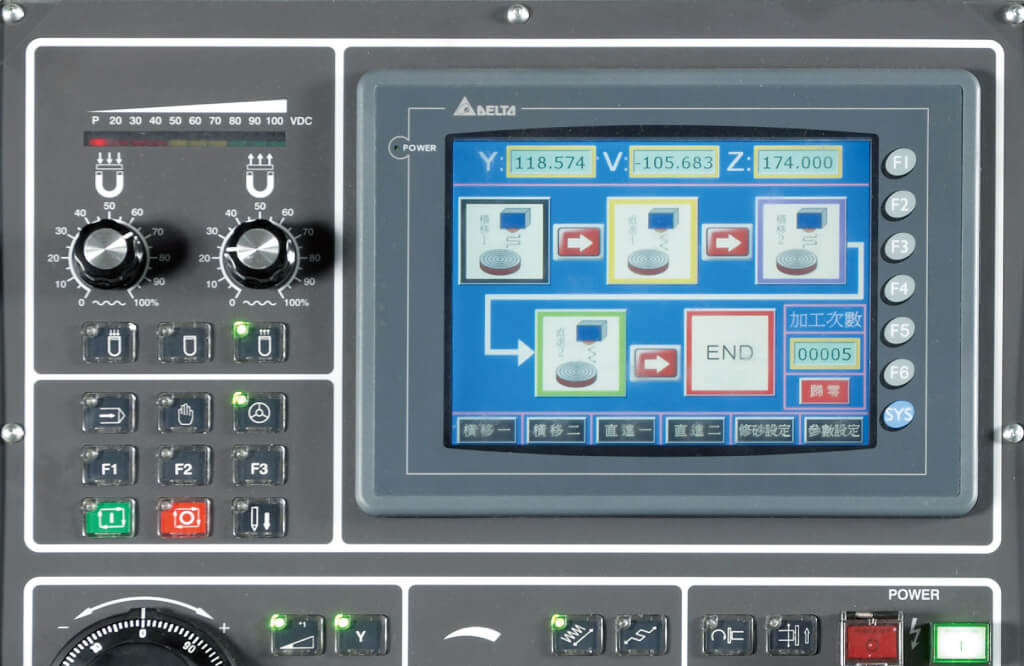

PLC Controls System

Shop floor user friendly language allows indexperienced operators to master the control. The simple dialog control requires only size inputo to start the grinding cycle

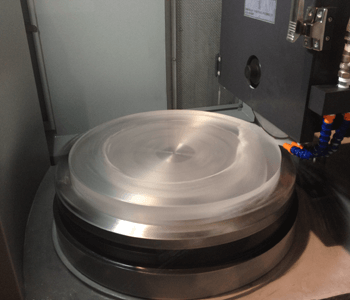

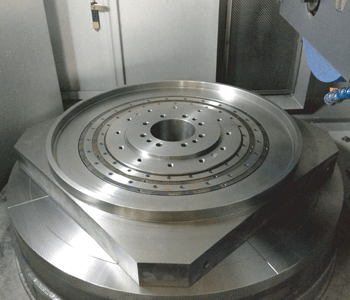

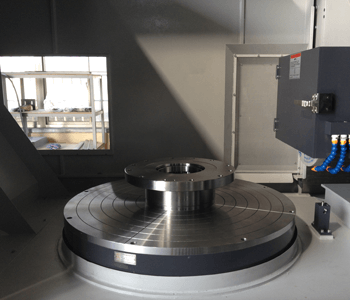

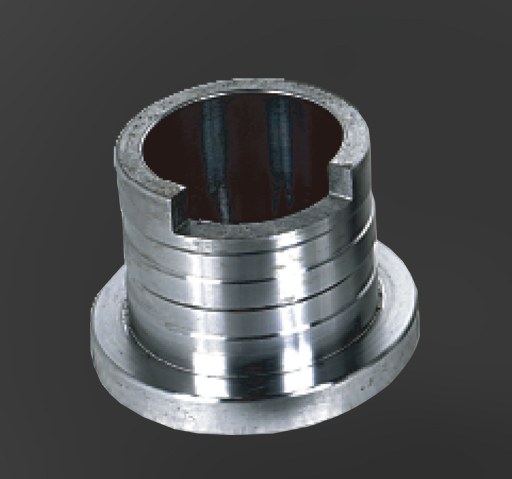

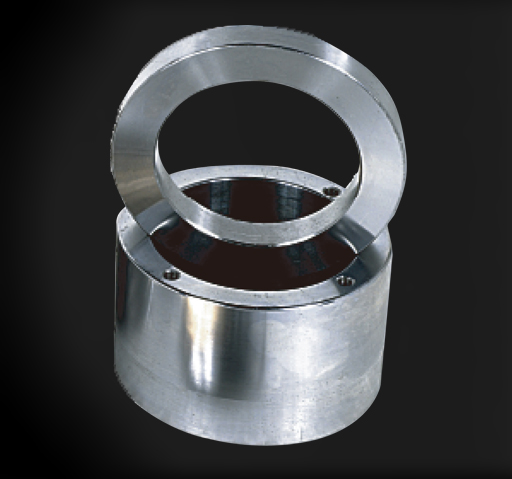

Grinding Sample

Specification

| Compare EHR-12 |

||||

|---|---|---|---|---|

| Description | Rotary magnetic chuck dia. | mm | 300 | |

| Maxi grinding radius. | mm | 175 | ||

| distance of table surface to spindle surface center. | mm | 360 | ||

| Rotary magnetic chuck speed. | rpm | 20-250 | ||

| rotary magnetic chuck horse power. | KW | 750W | ||

| spindle motor. | hp | 2 | ||

| spindle speed(50/60Hz) | rpm | 3000/3600 | ||

| Auto downfeed horse power. | Servo Motor 500W | |||

| Vertical hand wheel sownfeed per revolution. | mm | x1,x5,x10(MPG)/0.1,0.5,1 | ||

| Vertical hand wheel sownfeed per graduation. | mm | x1,x5,x10(MPG)/0.001,0.005,0.01 | ||

| wheel size(diaxwidthxbore). | mm | 180x13x31.75 | ||

| Net weight/gross weight. | kg | 1600/1800 | ||

| Packing size (LxWxH). | mm | 1820x1450x2020 | ||

| Max Table Load. | kg | 30 | ||

Optional accessories

| SIEMENS CNC controls Available |

| MITSUBISHI CNC controls Available |

| FANUC CNC controls Available |

| Magnetic rotary table |

| Basic coolant system |

| Coolant system with magnetic separator |

| Coolant system with paper filter and magnetic separator |

| Oil mist collector |

| Spindle motor inverter |

| Digital readout |

| oil line wheel balance system |

| Rotary diamond wheel dresser |

| Spindle chiller |

| Chuck demagnetizer |

| Coolant system with paper filter |

These machines can also be used for following variety of materials, semi-conductor, solar photonics, IC, Wafer, TFT-LCD,PASS ceramic products, aluminum oxide (A1203), Zirconium oxide (Zro2),Silicon nitride(Si3N4), Slilcon carbide(STC), Silicon (Si), Quariz, ZTA Graphite, MACOR, Ru etc. The variety of materials capable of being ground provides the customer exceptional versatility.

Feature:

- Precision grinding machine

- Surface finishing to mirror class

- Automatic Trim Compensation

- On line spindle vibration monitor

- Machine base fully supported design creating high rigidity structure

- Y, Z and rotary axis driven by AC servo motor