Grinding Applications

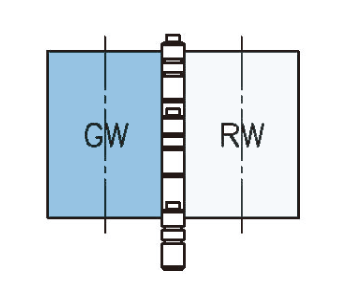

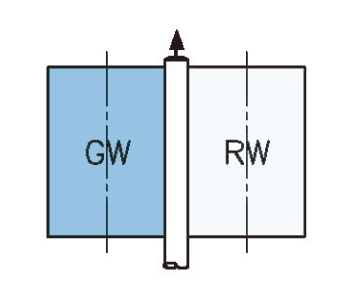

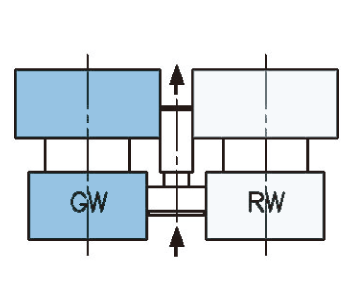

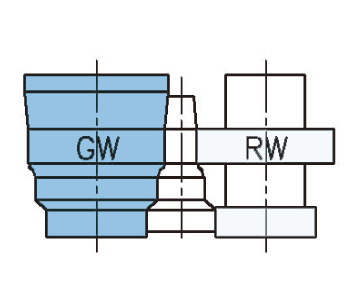

Thrufeed grinding

Thrufeed grinding

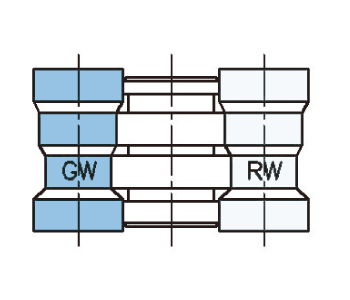

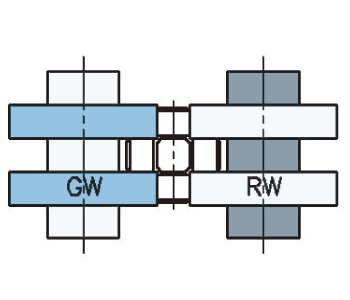

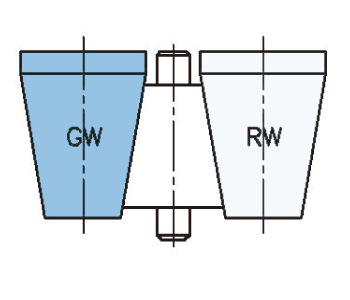

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

Infeed grinding

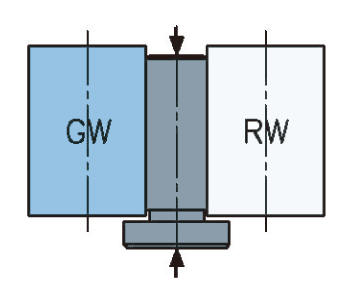

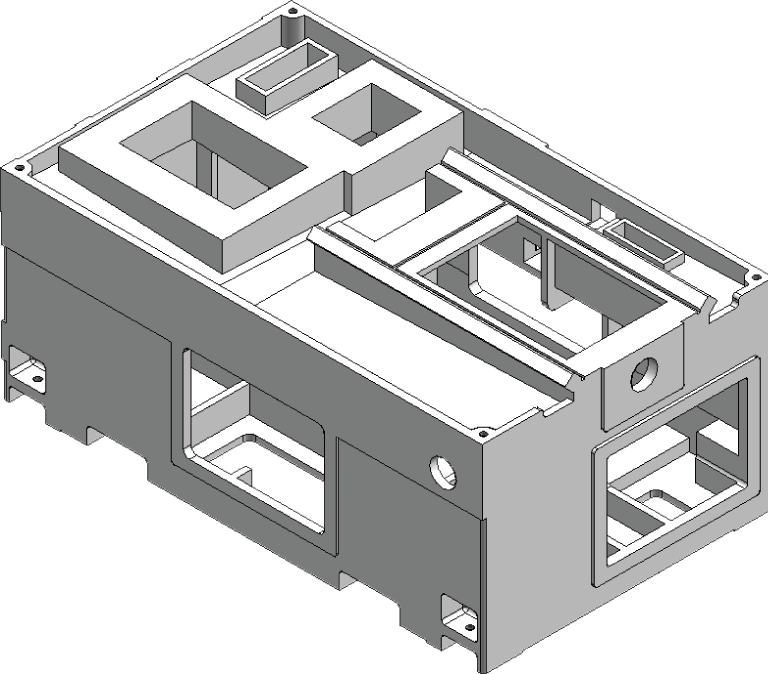

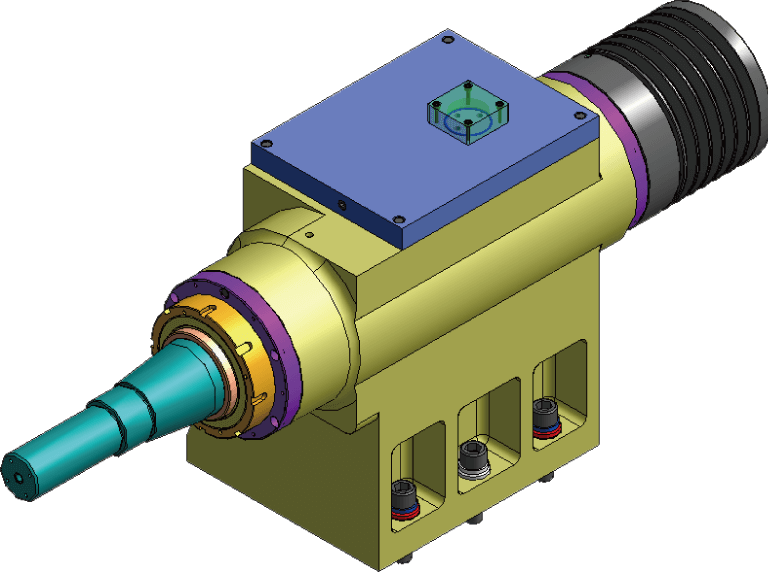

Machine Design Feature

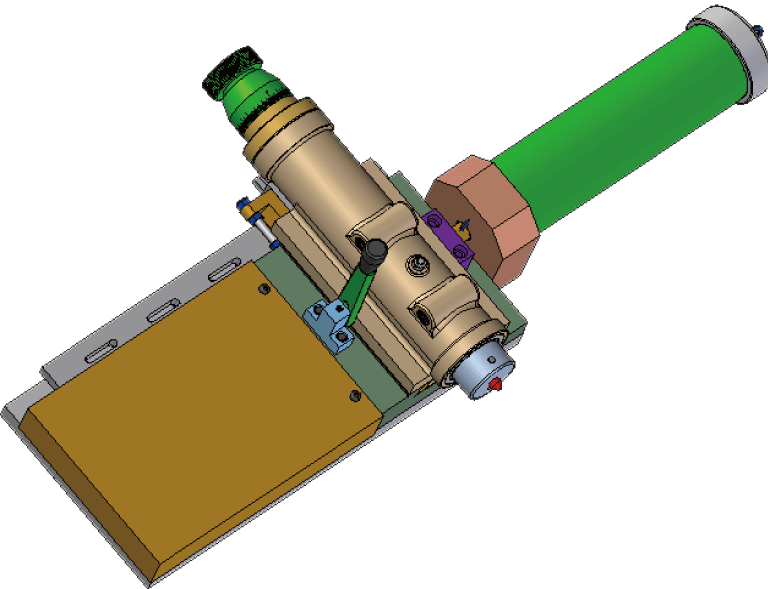

Blade Selection

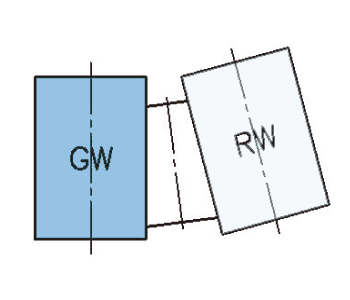

Due to different working diameters, the guide plate and regulating wheel must be parallel as this influences the grinding accuracy significantly.

Part name:Step shaft

Infeed grinding + auto-loading/unloading

Material:SCM415

Removed stock:Max. ∅0.2mm

Cycle time:25sec(loading/unloading included)

Roundness:1.5μm

Part name:Ball Piston

Infeed grinding + auto-loading/unloading

Material:SCM415

Removed stock:Max. ∅0.3mm

Cycle time:26sec(loading/unloading included)

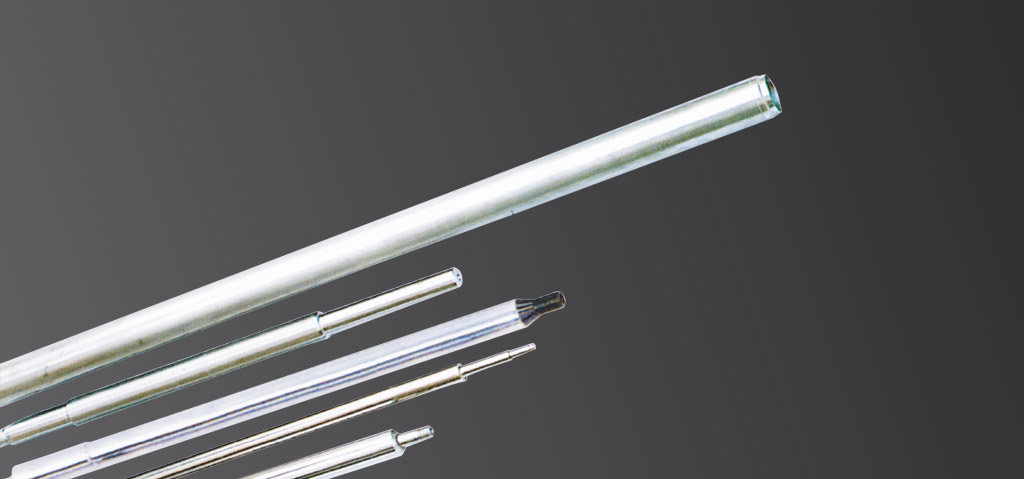

Part name:Piston pin

Thrufeed grinding

Material:SCr21H

Removed stock:Max. ∅0.13mm

Feedrate:3m/min

Roundness:1.2μm

Grinding Sample

Specification

| Compare ECG-S1206 |

Compare ECG-S1808 |

Compare ECG-S1810 |

Compare ECG-S1812 |

Compare ECG-S2008 |

Compare ECG-S2010 |

Compare ECG-S2012 |

Compare ECG-S2408 |

Compare ECG-S2410 |

Compare ECG-S2412 |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grinding Capacity | Work diameter (w/standard workrest) | mm | Ø1-30 | Ø1-60 | Ø1-60 | Ø1-60 | Ø1-60 | Ø1-60 | Ø1-60 | Ø1-80 | Ø1-80 | Ø1-80 | |

| Work diameter (w/special workrest) | mm | Ø30-50 | Ø60-100 | Ø60-100 | Ø60-100 | Ø60-120 | Ø60-120 | Ø60-120 | Ø80-150 | Ø80-150 | Ø80-150 | ||

| Grinding Wheel | Wheel size (OD x Width x ID) 08type | mm | φ305x150xφ120 | φ455x205xφ228.6 | φ455x205xφ228.6 | φ455x205xφ228.6 | φ510x205xφ304.8 | φ510x205xφ304.8 | φ510x205xφ304.8 | φ610x205xφ304.8 | φ610x205xφ304.8 | φ610x205xφ304.8 | |

| Wheel size (OD x Width x ID) 10type | mm | - | φ455x255xφ228.6 | φ455x255xφ228.6 | φ455x255xφ228.6 | φ510x255xφ304.8 | φ510x255xφ304.8 | φ510x255xφ304.8 | φ610x255xφ304.8 | φ610x255xφ304.8 | φ610x255xφ304.8 | ||

| Wheel size (OD x Width x ID) 12type | mm | - | φ455x305xφ228.6 | φ455x305xφ228.6 | φ455x305xφ228.6 | φ510x305xφ304.8 | φ510x305xφ304.8 | φ510x305xφ304.8 | φ610x305xφ304.8 | φ610x305xφ304.8 | φ610x305xφ304.8 | ||

| Motor rated power / max. torque | kw/Nm | 5.5/36(Opt. 7.5/49) | 11/71(Opt. 15/97) | 11/71(Opt. 15/97) | 11/71(Opt. 15/97) | 15/97(Opt. 18.75/120) | 15/97(Opt. 18.75/120) | 15/97(Opt. 18.75/120) | 15/97(Opt. 22.5/143) | 15/97(Opt. 22.5/143) | 15/97(Opt. 22.5/143) | ||

| Spindle speed | rpm | 2080 | 1400 | 1400 | 1400 | 1250 | 1250 | 1250 | 1050 | 1050 | 1050 | ||

| Dressing increment per gra./rev. | mm | 0.01 / 1.5 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | ||

| Regulating Wheel | Wheel size (OD x Width x ID) 08 type | mm | φ205 x 150 x φ90 | φ255x205xφ111.2 | φ255x205xφ111.2 | φ255x205xφ111.2 | φ305x205xφ127 | φ305x205xφ127 | φ305x205xφ127 | φ355x205xφ152.4 | φ355x205xφ152.4 | φ355x205xφ152.4 | |

| Wheel size (OD x Width x ID) 10 type | mm | - | φ255x255xφ111.2 | φ255x255xφ111.2 | φ255x255xφ111.2 | φ305x255xφ127 | φ305x255xφ127 | φ305x255xφ127 | φ355x255xφ152.4 | φ355x255xφ152.4 | φ355x255xφ152.4 | ||

| Wheel size (OD x Width x ID) 12 type | mm | - | φ255x305xφ111.2 | φ255x305xφ111.2 | φ255x305xφ111.2 | φ305x305xφ127 | φ305x305xφ127 | φ305x305xφ127 | φ355x305xφ152.4 | φ355x305xφ152.4 | φ355x305xφ152.4 | ||

| Spindle speed (infinite variable) | rpm | 15-310 | 15-310 | 15-310 | 15-310 | 15-310 | 15-310 | 15-310 | 15-310 | 15-310 | 15-310 | ||

| Upper slide infeed handwheel per gra./rev. | mm | 0.02 / 4 | 0.05 / 3.5 | 0.05 / 3.5 | 0.05 / 3.5 | 0.05 / 3.5 | 0.05 / 3.5 | 0.05 / 3.5 | 0.05 / 3.5 | 0.05 / 3.5 | 0.05 / 3.5 | ||

| Upper slide micro infeed handwheel per gra./rev. | mm | N/A | 0.001 / 0.02 | 0.001 / 0.02 | 0.001 / 0.02 | 0.001 / 0.02 | 0.001 / 0.02 | 0.001 / 0.02 | 0.001 / 0.02 | 0.001 / 0.02 | 0.001 / 0.02 | ||

| Swivelling angle (L/R) | deg | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ±5° | ||

| Inclining angle (F/R) | deg | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | +5° ~ -3° | ||

| Dressing increment(X1,Y1) per gra./rev. | mm | 0.01 / 1.5 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | 0.01 / 2 | ||

| Lower slide infeed handwheel (per gra./rev.) | mm | 0.05 / 7 | 0.05 / 9 | 0.05 / 9 | 0.05 / 9 | 0.05 / 9 | 0.05 / 9 | 0.05 / 9 | 0.05 / 9 | 0.05 / 9 | 0.05 / 9 | ||

| Lower slide micro infeed handwheel (per gra./rev.) | mm | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | 0.001 / 0.2 | ||

| Regulating wheel motor | kw | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 5 | 5 | 5 | ||

| Motors | Hydraulic motor | kw | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | |

| Machine | Net weight | kg | 1800 | 3300 | 3300 | 3300 | 3400 | 3400 | 3400 | 6100 | 6100 | 6100 | |

| Gross weight | kg | 2200 | 3600 | 3600 | 3600 | 3700 | 3700 | 3700 | 6600 | 6600 | 6600 | ||

| Packing size (L x W x H) | mm | 2260x1950x1820 | 2700x2240x1850 | 2700x2240x1850 | 2700x2240x1850 | 2700x2240x1850 | 2700x2240x1850 | 2700x2240x1850 | 3580x2240x2070 | 3580x2240x2070 | 3580x2240x2070 | ||

Standard accessories

| Tools and tool box |

| Standard coolant tank |

| Wheel extractor |

| Diamond dresser |

| Levelling bolts and blocks |

| Grinding wheel with flange |

| Regulating wheel with flange |

| Spindle lubrication system w/ cooling fan |

| Regulating wheel with flange |

| Manual lubricator for guide ways (S model) |

| Operation manual and part lists |

| Thrufeed workrest |

| Infeed workrest |

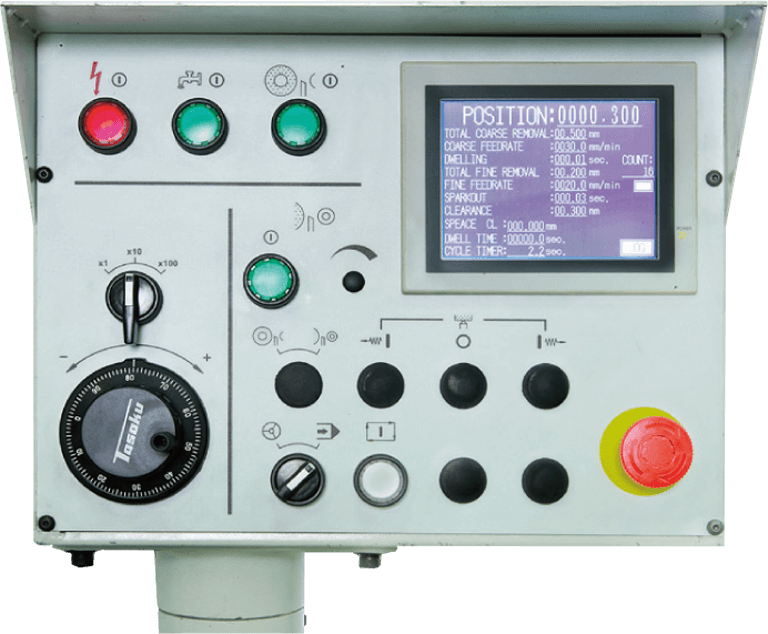

| Control panel (S model) |

| PLC controller + touch screen + control panel (NC model) |

| FANUC 0i-TF CNC controller (CNC model) |

Optional accessories

| Vibration feeder auto. loading system |

| Auto. unloading system for thrufeed grinding |

| Forming attachment (forming plates) |

| Coolant system with magnetic separator |

| Thrufeed blade (various sizes) |

| Infeed blade (various sizes) |

| Hydraulic forming attachment |

| Coolant system with paper filter |

| Coolant system with magnetic separator & paper filter |

| Infeed grinding workpiece eject attachment ( hydraulic / pneumatic ) |

| Auto. loading system for thrufeed grinding (Φ5∼25mm, L 50∼600mm) |

| Hopper type auto. loading system for thrufeed grinding (Φ2∼8mm, L 50∼180mm) |

| Input rail & output rail |

| Balancing stand/ arbor |

| Spare regulating wheel flange |

| Spare grinding wheel flange |

| CE standard electrical cabinet |

| Special workrest (for large dia. Workpiece) |

| Minor diameter workrest (dia. 0.7~8mm) |

- NC model: optional auto. grinding wheel dressing device enables count dressing, time dressing, or auto dressing and compensation

- CNC model: with two axes servo control and the automatic compensation system can precisely dress forms with complicated shapes.

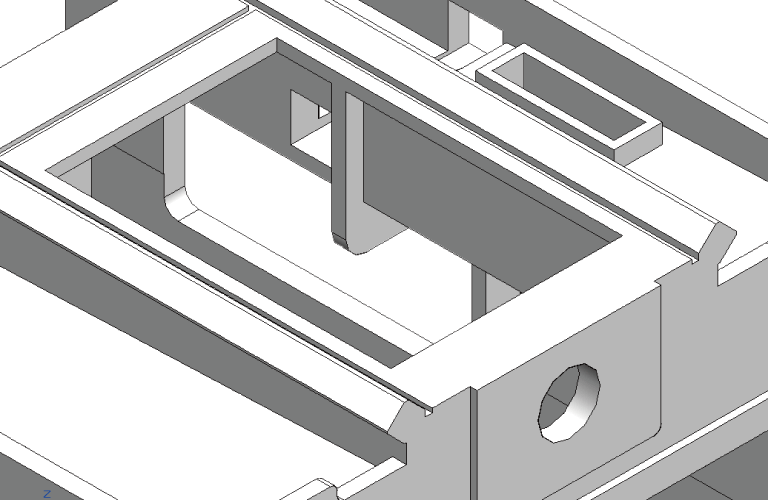

- Various workrest design: E-tech developed various kinds of workrest based on different diameter of workpieces, which are easy for operating adjustment.

An infeed grinding cycle can be completed by simply choosing the grinding cycle mode (single or automatic), inputting grinding data and then pressing cycle start.

ECG series high precision centerless grinder is different from other competitors, we use spectrum analyzer to precisely analyze the machine base inner ribs and casting thickness for greater rigidity. We offer hydrodynamic alloy bearing spindle with best rotation accuracy, suitable for heavy duty jobs, and drastically increase the spindle longevity.

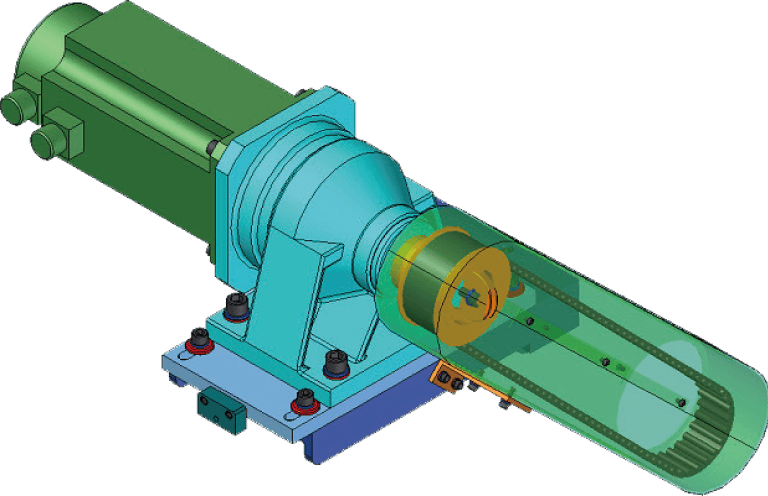

The S series is suitable for various kinds of shafts with thrufeed grinding operation. The servo motor on regulating wheel provides infinitely variable speeds for grinding and dressing speed adjustment, with timing belt transmission system which provides steady speed and torque performance.